Description

Delphin Technology Expert Logger is a new generation of data loggers. It combines the latest communication technology with advanced measurement technology and is based on FPGA technology to make it especially powerful. It can process up to 46 analog input channels at both low and high rates of sampling. Measurement data can be accurately acquired, independently stored, and transmitted to the internet or a PC for evaluation via USB, LAN, WLAN, or LTE.

Delphin Technology Expert Logger OPC UA Interface

OPC UA is becoming an increasingly established protocol and when used with the Expert Logger devices, measurement acquisition, monitoring, and test stand automation applications can be made ready for open data exchange data by Industry 4.0/Internet of Things.

Both OPC UA servers and clients have been integrated into the Expert Logger devices to enable fast, easy, and barrier-free data exchange with sensors and sub-systems also supporting OPC UA.

Many products such as frequency converters, controllers, and regulators have already fully integrated OPC UA. The opportunities provided by OPC UA have been identified within the measurement and sensor technology sector with several sensors and actuators now available with OPC UA interfaces.

In addition to OPC UA, Expert Logger devices are also equipped with PROFIBUS, ModBus, CAN-Bus, and serial interfaces for sensor and field-level connections.

Operation Made Simple

Sensors are connected via plug-in screw terminals and a chart clearly shows how channels are arranged. Users always have a good overview of the channels despite their high density. Each set of four terminals can be configured as two differential inputs to measure voltage, currents, and thermocouples, or to take measurements from a 4-wire RTD.

Configuration – Fast and Easy

The Expert Logger is simple to configure from a PC. These settings remain stored within the Expert Logger even when disconnected from the power supply. The device settings can also be read out and stored on a PC and analyzed offline without the need for a connected Expert Logger. The offline configuration settings are then simply read into the device when connected. The software used for configuration is simple to operate to let users fully focus on their measurement tasks.

Intelligent signal processing

Signal processing using internal software channels significantly simplifies measurement tasks. Flexible calculation channels enable measurement data to undergo further computation and recording. Integrators directly calculate volumes or quantities from time-related measurement data such as mass and discharge flow rates. Limit values can monitor measurement data and be used to switch digital outputs or automatically send emails.

Complex signal processing is possible using pulse counters, stop-clock functions, and operating-hours counters. Averages can be calculated and recorded as time-weighted or moving. The Expert Logger‘s software channels set it apart from other loggers and make it very popular among users.

Product Features

- Universal analog inputs (mV, mA, TC, RTD)

- SDI12 interfaces for environmental sensors

- Independent operation is possible with batteries or rechargeables

- Minimal energy consumption via a sleep function

- 2 .. 14 GB of internal data storage for up to 420 million measurement values

- PUSH function to send measurement data to the internet

- WLAN link to PCs and mobile devices

- LAN and USB interface to a PC or network

- Monitoring and data logging in a single device

Applications with Expert Logger

- Data logging

- Environmental measurement technology

- Product testing

- Measurement data diagnosis

- Lab data acquisition

- Trials and tests

- Energy optimization

Delphin Technology Expert Logger Model :

Universal, Communicative, and Reliable

Expert Logger is available in four versions which differ only in the number of analog and digital inputs they can process. All Expert Logger devices are equipped with internal 2 .. 14 GB memories that can independently store up to 420 million measurement values with date and time stamps to msec precision.

Storage capacity can be extended as required via external USB or LAN storage devices (NAS). An integrated, energy-saving “sleep function“ automatically switches off the device during breaks in measurement acquisition. The Expert Logger operates with standard batteries, rechargeable batteries, or solar units.

Precision measurement is ensured through the use of a 24-bit converter. Voltages can also be precision recorded to the ?V range. All channels are galvanically isolated to suppress earthing loops and the tried and tested input circuitry protects the device against voltage spikes.

Electromechanical components are avoided (relays multiplexer), and the device operates noise and maintenance-free. Delphin‘s patented analog inputs guarantee years of reliable measuring work.

Expert Logger Interfaces

Versatile interfaces of the device allow the connection of PCs via LAN, WLAN, or USB. PLCs can be easily connected via the ProfiBus or ModBus interfaces. A remote connection is optionally possible with an integrated 3G / 4G modem.

- 1 x LAN (1 x 1000BaseTX)

- 1 x USB Master (2.0)

- 1 x USB Device (2.0)

- 1 x SDI12 (by using deleted 1xDI and 1xDO) (only 100 and 200)

- 2 x CAN Bus (2.0)

- 3 x RS232/485 (2 x PROFIBUS Slave, Modbus RTU, ASCII Protocol)

- 1 x WLAN or WWAN (optional)

Expert Logger Accessories

- Rechargeable pack for energy-independent operation

- External data storage

- UMTS / LTE module

- WLAN module

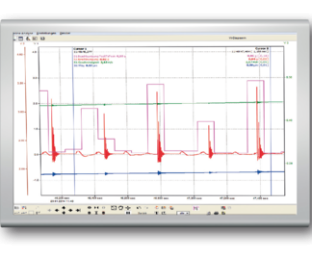

Measurement Data Analysis

ProfiSignal Go enables users to portray measurement data online and offline and to carry out detailed analyses. The software can portray the Expert Logger‘s measurement data in trends. Users can choose between y(t) or y(x) diagrams as well as a range of other analysis diagrams. ProfiSignal Go is especially intuitive to make it highly user-friendly.

A range of options

- Online/offline analysis and diagnosis of measurement data

- A range of trend formats y(t), y(x), digital signal analysis

- ASCII / CSV / TDM data exporting

- Output or export of trends as EMF files

- Analysis using cursor functions

Offline data evaluation is easy and quick to perform. The software also enables fast ASCII exporting of the measurement data for MS Excel™, or conversion into TDM format. Our customers tell us that it is a pleasure to use ProfiSignal Go.

Technical Specification

Device Type | 100 | 200 | 300 | 400 |

| Analog inputs (mV, mA, TC) | 16 | 32 | 46 | 16 |

| Appropriate for RTD’s | 8 | 16 | 23 | 8 |

| Total sampling rate | 1000 Hz | 2 groups per 1000 Hz | 3 groups per 1000 Hz | 1000 Hz |

| Voltage measurement ranges | ±156 mV .. ±10 V | |||

| Current measurement ranges | 0 .. 20 mA, 4 .. 20 mA, free | |||

| Current reference for resistance measurement | 100 ?A, 200 ?A or 1 mA (4-wire); 2 x 200 µA (3-wire) | |||

| Resistance measurement ranges | 0 .. 100k? | |||

| Resolution / Type ADC | 24-bit Sigma-Delta | |||

| Input impedance | 1 G? | |||

| Internal reference junctions | yes / 2 | yes / 4 | yes / 6 | yes / 2 |

| Withstand voltage / galvanic isolation | ±110 VDC / ± 400 VDC to PE, another channel group | |||

| Measurement accuracy | V/mA: 0.01% of upper range value RTD’s: 0.1 K (4-wire connection), Thermocouples (external thermoblock): 0.3 K after compensation Thermocouples (internal reference junction): < 1.0 K compensation Resistance measurement: 0.02% of upper range value (4-wire connection) | |||

| Strain Gauge Voltage Excitation | 1 | 1 | 0 | 0 |

| Voltage | internal: 5 VDC ± 10 mV, external: 1 / 2.5 / 5 / 10 V | |||

| Analog Outputs | 0 | 0 | 0 | 6 |

| Resolution | 16 bit | |||

| Output ranges | 0 .. 10 V / ± 10 V / 0 .. 5 V / ± 5 V / 0 .. 12 V / ± 12 V / 0 .. 6 V / ± 6 V / 0 .. 20 mA / 0 .. 24 mA / 4 .. 20 mA | |||

| Galvanic isolation | ±400 VDC to system / PE | |||

| min. load/max. burden | 625? / 950? | |||

| Number of Digital Channels | ||||

| Digital inputs up to 1 MHz | 3 | 3 | 0 | 0 |

| Digital inputs up to 250 Hz | 1 | 1 | 0 | 1 |

| Digital outputs | 4 | 4 | 0 | 0 |

| Digital inputs/outputs | 4 | 4 | 1 | 24 |

| Technical Information Digital Inputs | ||||

| Input signal | low: 0 .. 1V / high: 5 .. 100 VDC@3,5 mA | |||

| Frequency range/width counter | 0,2 Hz .. 1 MHz, respectively 0,2 Hz .. 250 Hz / 64 bit | |||

| Galvanic isolation | ±400 VDC to PE / other channels | |||

| Technical Information Digital Outputs | ||||

| Max. switching voltage/current | 50 V / 2,5 A for 2 seconds, 250 mA continuous current | |||

| PWM function / Pulse duty factor | Basic frequency 5 Hz .. 10 kHz / 1:1000 | |||

| Galvanic isolation | ±400 VDC to PE, other channels | |||

| Data storage | ||||

| Data storage internal | 2 .. 14 GB (approx. 30 million measurement values per GB) | |||

| Data storage external | USB, NFS, CIFS, (S)FTP | |||

| Interfaces/Protocols | ||||

| Sensor bus SDI12 | 1 | 1 | 0 | 0 |

| COM1 and COM 2 | RS485, 9-pole sub-D socket / ASCII / Modbus RTU master & slave / PROFIBUS DPV1 slave | |||

| COM 3 | RS232, 9-pole sub-D plug / ASCII / SCPI / Modbus RTU | |||

| LAN | 1 x 1000 Base-T | |||

| WLAN (optional, alternative to WWAN) | 802.11 b/g/n | |||

| WWAN (optional, alternative to WLAN) | UMTS, LTE max. 100 Mbit/s | |||

| USB | Device 2.0 Host / 2.0 / low/high/full | |||

| TCP / IP | Modbus TCP server & client, OPC UA server & client | |||

| CAN / RS 232/485 | 2x CAN 2.0 / Modbus RTU master & slave, SCPI, ASCII, SMTP, NTP, PTP | |||

| General Technical Information | ||||

| Dimensions/weight | H 217 x W 88 x D 128 mm / 750 g | |||

| Fixing | Rail mounting DIN EN 60715 or screw fixing | |||

| Signal connections | Plug-in screw terminals, 96 terminals in 2 rows, max. 1.5 mm² | |||

| Temperature range | -20 .. 50 °C* | |||

| Humidity | max. 90 % relative humidity, non-condensing | |||

| Power supply | 12 .. 24 VDC / ± 10% | |||

| Power input normal mode | max. 15 W | |||

| Power input sleep mode | 5 mW@12 V, 10 mW@24 V | |||

* Sufficient air circulation in the control cabinet must be ensured. Registered: 24.04.2020

Other Article: