About Philmac UltraPHIL Float Valves

High-quality, reliable brass float valve that can be used in tanks and troughs up to 1,500 litres for a variety of plumbing, agricultural, and industrial applications. ASNZ 4020 and Watermark have been authorised for use with potable water.

Philmac horizontal float valves, which are quick and simple to install and guarantee a consistent water level, are based on a straightforward but efficient functioning principle. The most demanding plumbing, commercial and residential applications may be handled by Philmac’s adaptable valve line.

The sturdy plastic materials and premium brass or stainless steel valves are safe for drinking water and do not contain any toxins or impurities. Additionally, they can be used when the tank water is later heated to a maximum temperature of 95° Celsius.

Designed to make the job at hand so much easier and backed by a full range of spare par ts, these valves will deliver years of reliable operation.

Application of Philmac UltraPHIL Float Valves

- Agriculture: Stock troughs and water tanks.

- Plumbing: Hot and cold water storage tanks for domestic and industrial applications

- Industrial: Dishwashers and hospital sterilizers

- Commercial: Air-conditioning units.

Benefits of Philmac UltraPHIL Float Valves

Fast and Easy Installation

- Choice of Threads: Philmac offers a range of parallel (fastening) threads or tapered (sealing) threads which makes them suited to a variety of installations. This includes troughs/tanks with pre-fitted tapered inlets or tanks where only a pre-drilled hole exists.

- Easy Disassembly:The valves have been designed for easy replacement of the rubber seal. Simply remove the pivot pin, disconnect the lever assembly and remove the body cap (where fitted) to allow the piston to slide out and access the seal.

- Minimum Space Required for Installation: Based on a compact body design and a range of lever lengths in the ½” range they are perfect for tight applications such as industrial dishwashers.

- BSP Inlet Threads: The Plumbing and Irrigation sectors use British Standard Pipe (BSP) threads as a standard. Philmac also uses these thread types across the valve range to ensure compatibility with other threaded fittings and make installation easy.

Complete Security

- Corrosion Resistant:

Brass Valve -The bodies, plungers, lever assemblies, backnuts, collars, and pivots pin are manufactured from DZR brass. With a stainless steel seat as standard, it means years of hassle-free operation.

Plastic Valve – The bodies, seats, backnuts and plungers are manufactured from plastic. The lever assemblies and pivot pins are manufactured from DZR brass ensuring longevity of the valve.

Stainless Steel – All components, except the seal, are manufactured from stainless steel for high chemical resistance. - Reliable Operation: High-quality engineered components mean years of reliable operation.

- Positive Shut-Off: The action between the lever assembly and plunger assembly ensures the plunger assembly provides a complete seal against the water inlet and prevents unwanted loss of water.

- Approvals: All valves comply with Australian/New Zealand Standard 4020 which means the valves are suitable for use with drinking water

High Performance

- Manufactured from DZR brass: Philmac brass float valves are manufactured from dezincification resistant (DZR) brass which means the brass is resistant to corrosion involving the loss of zinc leaving a residue of spongy or porous copper.

- Manufactured from engineering-grade thermoplastic materials: Philmac plastic float valves are Australian-made and manufactured from lightweight high-performance thermoplastic materials which have excellent impact, UV, and corrosion resistance. The material is non-toxic and taint-free.

- High-pressure shutoff: Horizontal float valves are rated to a pressure of 1400 kPa (200 psi) (static shutoff). This is based on using the standard lever arm and recommended float (ball) size.

Complete Coverage

- Wide range: The range of float valves is comprehensive and includes sizes from 3/8” to 2”(DN10 to DN50). In addition, the ½” range is offered with tapered or parallel thread configurations and lever lengths.

Standards and Tests of Philmac UltraPHIL Float Valves

Philmac’s range of horizontal float valves are designed to comply with the following standards and undertake a range of tests to ensure they comply with these standards.

Standards

- AS1910: Water Supply – Float control valves for use in hot and cold water.

- AS/NZ 4020: Testing of products for use in contact with drinking water.

- AS1722.1: Pipe threads of Whitworth form par t 1: sealing pipe threads.

- AS1722.2: Pipe threads of Whitworth form part 2: fastening pipe threads.

- ISO7: Pipe threads where pressure-tight joints are made on the threads.

Tests

- Shut Off Test: Valves are tested for shut off against a hydrostatic water pressure of 2000 kPa (290 psi) or 20 bar.

- Strength Test: Valves are tested for adequate strength for their intended application. This includes testing at the maximum recommended operating temperature and a pressure of 3000 kPa (435 psi) or 30 bar.

- Endurance Test: Operating mechanisms are subjected to 50,000 cycles. This simulates opening and closing operations during the design service life of the valve.

Installation Instruction of Philmac UltraPHIL Float Valves

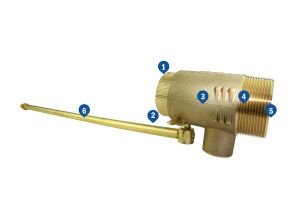

The Philmac horizontal float valves operate by opening and closing a plunger against a seat through the action of a lever arm attached to a float. The lever arm is interconnected to the plunger via a cam. As the water level drops, the float and lever arm move in a downward direction allowing the plunger to move away from the seat, which opens the valve. When the water level rises, the float and lever arm move in an upward direction and the plunger moves towards the seat until it sits firmly against the seat and shuts the valve off.

Tapered Thread

- Apply PTFE tape or approved sealant to the thread ensuring a sufficient amount is applied to guarantee a water-tight seal.

- Screw the valve into the female thread by hand until firm*.

- Using a pipe wrench or multi grips on the body** of the valve, screw it into the female thread until tight. Where necessary ensure the female thread is held stationary to avoid it from moving.

Parallel Thread

- Remove the backnut and slide the thread through the appropriate-sized hole.

- When using the stem sleeve to fit the valve into ¾” holes, ensure it is properly located on the valve side of the installation to prevent the valve from moving

- Refit the backnut and tighten it with a spanner. The valve body** can be held in place with a spanner, multi-grips, or equivalent.

Adjusting Lever Arm

- Where necessary bend the lever arm to adjust the water level. This can be done by removing the lever arm assembly by first straightening the tabs on the end of the pivot pin with a pair of pliers and then sliding it out.

- By using a pair of multi-grips or equivalent the lever can then be bent to the necessary angle.

- Adjust the lever arm and then refit. Once the correct lever arm angle is achieved ensure the pivot pin tabs are flared outward by using a small screwdriver.

Source: Philmac.com

Read More Articles:

- SkimOil Mini-Brute Oily Water Separators

- SkimOil Brute Marine Oily Water Separator

- SkimOil Grinder Oil Skimmer

- SkimOil Floating Tripod Oil Skimmer

- SkimOil Fracking Oil Removal System