General Information

Amflow Instruments has specialized in the design & development of precision flow control devices used for surface and sub-sea chemical injection applications.

Amflow® self-regulated flow control products not only offer the highest turndown ratios in the oil industry, they also are configurable for remote automation. Amflow Instruments engineer a wide range of innovative products including; actuators, back pressure regulators, filters, and flow control valves for high and low-pressure flow control.

Amflow products and unique approach to automated chemical injection significantly improves flow control capabilities and reduces maintenance costs.

Amflow Instruments Product

Amflow Instruments Electronic Actuators

Amflow® Electronic Valve Actuators are ATEX certified for use in hazardous areas and engineered for surface chemical injection flow control applications. All electronic actuators feature low power consumption, high accuracy, repeatability, and the ability to consistently operate under a wide range of conditions.

All of Amflow® Electronic Valve Actuators have communication capabilities for remote automation control. They are designed to support Industrial Ethernet and various communication modules including HART/4-20mA, H1 FOUNDATIONTM Fieldbus, Modbus RTU/ RS485, or Modbus TCP.

Back Pressure Regulators

Amflow® Back Pressure Regulators represent the latest technology in back pressure regulation. Like Amflow® Flow Control Valves, our back pressure regulators require a low actuation force which allows for easy conversion to automation. The PR7B and PR7B-HP Back Pressure Regulators are designed for surface regulation and may be combined with any Amflow® Electronic Actuator, while the PR15 is designed for high flow/high-pressure use.

PR7B Back Pressure Regulator

Amflow Instruments Filters

Amflow® Filters offer a wide range of filter options for pressures from 275 bar (4,000 PSI) up to 920-bar (13,340 PSI). All filters incorporate a reusable filter element that can be backflushed for cleaning purposes. Max. Differential Pressure (Outside to Inside): 35 bar Max. Differential Pressure (Flow-through with Back-Flush): 10 bar

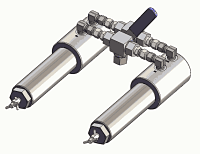

Dual Filter

The Simplex Filter Series is available as either a single assembly or dual assembly. The dual assembly allows the operator to switch between filter assemblies in order to replace filter elements without having to shut down the system for filter maintenance.

Strainers

Amflow Instruments Strainers are designed to be incorporated into systems for purposes of straining large particles prior to the pump suction. Amflow® offers a standard strainer, in addition to a second option which may be operated as either a filter or a strainer. Both operate with pressures up to 40-bar (580 PSI).

Flow Control Valves

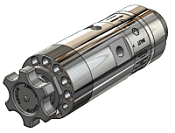

Amflow Instruments Flow Control Valves represent the latest technology in patented Dual Piston technology developed by A & H Enterprises. Our ATEX-certified chemical injection valves have the highest turndown ratio in their class, operating over a far wider range of flow rates than traditional valves, with repeatability and accuracy within ± 3% full range. All of Amflow’s® Flow Control Valves can be configured for an automated or manual flow rate adjustment.

Flow control is set by the internal pressure of the valve and not the overall system pressure, allowing for minimal operating torque for flow adjustment and easy adaptation to automation.

AM7B Series Flow Control Valve

Reference: amflow.com

Another Article:

- Quality Gauge & Valve Quality Series Q156

- Hengstler Thermal Printers XPM-80

- Hengstler Thermal Printers eXtendo X-80

- Bamo Electrically Actuated 3-Way Ball Valve VE3V – Stainless Steel

- Hengstler Safety Relays Type RDA