SKF Rolling Bearings are used to reduce friction between two surfaces moving relative to each other. Specifically, roller bearings bear radial, axial, or a combination of both loads by using cylindrical or needle-shaped rolling elements. By utilizing rollers as rolling elements, these bearings allow for smooth and efficient movement.

Also, these car bearings can minimize the wear that occurs on the contacting surfaces. Roller bearings are important in a wide range of industrial applications, from household appliances to production and transport machinery. Their main advantages include the ability to bear high loads, resistance to high speeds, and the ability to adapt to various operating conditions.

Principles of rolling bearing selection

Optimization of the performance, durability, and cost efficiency of a piece of equipment depends largely on proper bearing selection. The bearing selection process involves evaluating various technical parameters, such as the type of load, speed, temperature, and operating environment. By drawing up accurate bearing specifications, you can ensure the equipment achieves the expected level of performance.

When selecting bearings for any purpose, ultimately you want to be certain of achieving the required level of equipment performance – and at the lowest possible cost. Robustness is also very important because the conditions in which your equipment is assembled, operated and maintained may not be precisely known and may, in fact, vary over time.

In addition to the bearing rating life, there are key factors you must consider when putting together the bearing specifications for an application, including:

- Lubricant and supply method

- Shaft and housing fits

- Bearing clearance class

- Cage material and guidance

- Dimensional stability

- Precision requirements

- Bearing sealing

- Mounting method and maintenance

Benefits

- friction resistance and small power consumption, high mechanical efficiency, and easy to start.

- size standardization, interchangeability, easy to install and disassemble, and easy to repair.

- The structure is compact, the weight is light, and the axial size is narrower.

- High precision, large load, and long service life.

- Some bearings have automatic heart adjustment performance.

- It is suitable for mass production, the quality is stable and reliable, and the production efficiency is high

- The axial size is smaller than traditional fluid dynamic bearings.

- Radial and thrust combined loads can be borne simultaneously.

- In a large load-speed range, the unique bearing design can achieve excellent performance.

Bearing Size

The operating conditions of the application determine which of these factors most influence the performance and life of the bearing.

This section provides guidance on determining the required bearing size. The effect of RCF or permanent deformation on rolling elements and raceways is directly related to bearing size. Effects of cage type and material are not related to bearing size. In capped bearings, the effects of the lubricant and integral seal are only indirectly related to bearing size.

Therefore, the two main criteria that can be used for determining appropriate bearing size are:

- Size selection based on rating life

- Size selection based on static load

Bearing Accessories

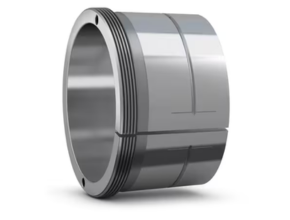

Adapter Sleeves

Adapter sleeves are versatile components that make it easy to install tapered hollow bearings on various types of shafts. Its simple and flexible design allows accurate placement of the bearing without requiring additional modifications to the shaft.

Withdrawal sleeves

A puller sleeve is a useful tool for mounting bearings on a stepped shaft. It works by pushing the bearing into the shaft and then locking it using a special lock nut. This nut is equipped with a keyway to ensure the bearing does not shift.

Lock nuts

Lock nuts are special bolts used to tighten and hold various machine parts, such as bearings or gears. To prevent them from coming loose easily, lock nuts are equipped with additional locking systems, such as special grooves or slots. This is important to keep all machine components in place and working safely.

Read More:

- MarelliMotori Oil & Gas B_E

- Thompson JSV series centrifugal pump

- SIMPLEX – TrueAlert Non Addressable Notification Appliances & Speakers

- Eurofyre fire detection and safety

- Vermont Gage Metalworking Industry

Source : SKF.com