Bearings are machine components that serve to reduce friction between two components that move relative to each other. Imagine like a wheel spinning on its axis, this bearing is what allows the wheel to rotate smoothly without much resistance.

Where bearings have several functions, namely supporting the shaft, minimizing friction, and bearing loads. The purpose of using bearings is to reduce friction that can cause heat, facilitate movement so that the machine moves more freely and smoothly, and support the load acting on the shaft or moving component.

The Type of Bearings

Rolling Bearings

Rolling bearings support and guide rotating or oscillating machine elements – such as shafts, axles or wheels – and transfer loads between machine components. They provide high precision and low friction allowing high rotational speeds while reducing noise, heat, energy consumption and wear. Rolling bearings are cost-effective, interchangeable machine elements that typically follow national or international dimensional standards.

As the name implies, roller bearings use a roller shaped like a cylindrical tube as a support that has contact between the inner race and outer race that does not rest on a single point like a ball bearing. The performance of roller bearings is quite good because they are able to withstand moderate to heavy loads, especially vertical and horizontal loads, depending on the position where the roller bearing is installed.

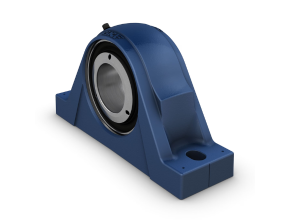

Mounted Bearings and Housings

Mounted bearings and housings with rolling bearings support a rotating shaft, which can be bolted on a machine frame or any other substructure. There is no need to precisely machine a bearing housing in a surrounding casing. This makes these solutions cost-efficient and easy to use, while providing full rolling bearing performance.

Super – Precision Bearings

With high running accuracy, high-speed performance and high system stiffness, SKF super precision bearings are ideal for machine tools and other precision applications, such as high-speed finishing mounts for steel wire, race car engines and transmissions, and innovative fluid treatment applications. These bearings also minimize noise, vibration and heat.

Our product range includes various bearing steel grades, including SKF’s trademarked NitroMax (for certain designs), which gives you up to three times longer service life than standard steel bearings and hybrid bearings with ceramic rolling elements, which are particularly suitable for high-speed applications. New advanced materials and designs are in the implementation phase and will soon be available to support your needs for increased productivity.

Slewing Bearings

Slewing bearings consist of an inner ring and an outer ring, one of which is usually geared. Together with mounting holes in both rings, they enable optimized power transmission with simple and fast connections between adjacent machine components. Bearing races, together with rolling elements and cages or spacers, are designed to accommodate loads acting singly or in combination, and in any direction.

SKF manufactures standard and customized slewing bearings in a variety of designs, with outside diameters from 0.1 to 18 m to meet specific application demands.

Plain Bearings

Plain bearings are used in many industries and across many applications where there is a need to cost-efficiently and reliably meet the challenge of oscillating movements and possible misalignment. From railways, mining and construction equipment, farm and forestry machinery, all the way to forklift trucks and solar power equipment.

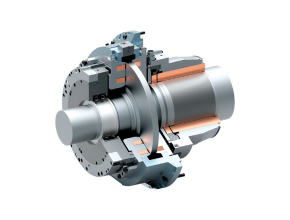

Magnetic Bearings and System

Features and benefits:

- High reliability and energy efficiency

- Low maintenance

- Oil-free and contamination-free

- High damping properties make the bearings withstand high transient loads and allow active control of the shaft unbalance

- Instantaneous and unlimited start/stop operation in vacuum and process gas, enabling machines with a sealed design

- Built-in monitoring system

Thin Section Bearings

Thin section bearings are designed to save weight, use less space, reduce friction, increase design flexibility and provide high operating accuracy.

These bearings can meet very demanding and specific requirements. They are often used in applications such as aerospace, medical systems, robotics, astronomical instrumentation, and machine tools. The efficiency of our designs can result in significant space, weight, and cost savings over standard dimensioned bearings.

Read more:

- Eclipse Magnetics separators

- Thompson Rotary Wellpoint Pumps

- Wago Interface Electronics Power Supplies

- SC Hydraulic Engineering D6 & 10-6 Liquid Pump

- Cast Iron Armature Bulgaria SA

Source : SKF.com