Hoffer Flow Controls Introductions The development of the modern turbine flowmeter can be traced back to David Potter, founder of Potter Aeronautical. Potter pioneered the development of the turbine flowmeter for the Navy in the 1940s. The initial application for the Potter turbine flowmeter was in fuel flow measurement for Navy aircraft. Today fuel flow […]

Pengenalan Selama bertahun-tahun,, orang-orang yang terlibat dalam industri minyak dan gas telah berinovasi dan menciptakan cara untuk mendapatkan pengukuran yang akurat pada flow meter migas. Dari mengekstraksi hingga mengirimkan bahan mentah ini, semua orang di bisnis ini telah berinvestasi secara mendalam untuk mendapatkan pengukuran yang seakurat mungkin. Dengan demikian, para ilmuwan dan insinyur telah bekerja […]

Description Ryuki GCF Multifunctional digital differential pressure type flow meter that can select the instantaneous flow rate and integrated flow rate measurement. It is used in air conditioning water lines, pure cooling devices, etc., and can handle up to a maximum diameter of 300A Ryuki GCF Specification Measuring fluid Liquid (fluid that does not corrode […]

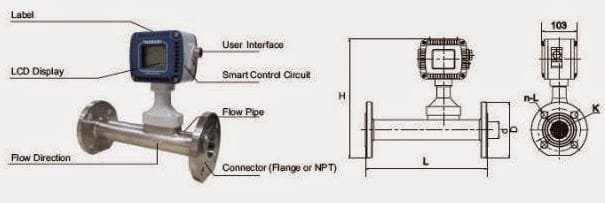

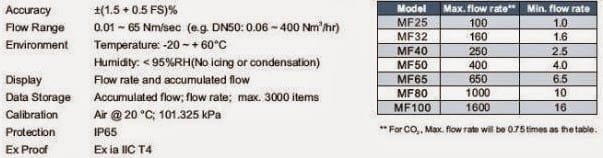

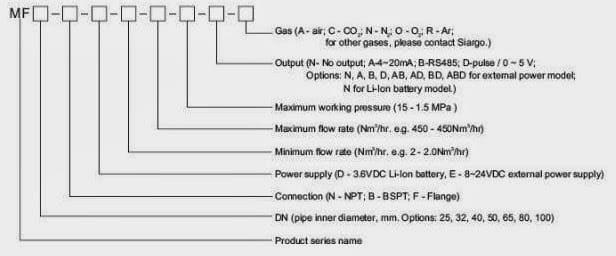

Inline Thermal Mass Flow Meter MF Series

MF series mass flow meters are designed for all purpose industrial gas metering and control. The meters provide direct mass flow information as well as well-designed user friendly interfaces (RS485/4~20mA/pulse etc.) for data process. The series cover the DN range from 25 to 100 mm with an accuracy of ±(1.5+0.5FS)% or better depending on the requests.

The meters can work at an environment of -20 to 60°C and pressure up to 1.5 MPa. The package ensures hygienic safety and can be used for beverage and food industrial gas process such as CO2. Other applications include special gas monitoring in steel process, hydrogen flow control in chemical industry, process gases (oxygen, nitrogen, helium, compressed air or argon) monitoring in manufacture, to name a few.

Features and Applications

- – Directly sense mass flow using thermal mass flow principle

- – Proprietary MEMS sensor design for better reliability

- – Standard 8 ~ 24 V power supply

- – Low pressure loss reducing energy cost

- – Industrial standard communication ports for easy networking and remote control

- – Large data storage capability for data log and analysis

- – Hazard proof (Ex ia IIC T4) or Class I Division I, (Zone 0) Groups A-D

Mechanical Dimensions

Product Selection

Thermal mass flowmeters are most commonly used to measure the mass flow of clean gases, such as air, nitrogen, hydrogen, helium, ammonia, argon, and other industrial gases. Mixtures, such as flue stack flow and biogas flow, can be measured when their composition is known. An advantage of this technology is its dependence on thermal properties […]

Specifications : Style: Remote Insertion Mass Flow Meter Sensor: Two reference-grade platinum RTD clad in 316SS sheath Material: Wetted metal components: 316SS Power: 24VDC Standard (12VDC or 115/230VAC optional) Power Dissipation : Electronics: Remote-Style Microprocessor-based (Hybrid-Digital) Probe Enclosure: Junction Box is Explosion Proof, Class I, Div 2, Groups B, C, D (no electronics) Transmitter Enclosure: […]