About Flow – Teknik

Flow-Teknikk – Process Instruments With a long track record in the industry, and employees with over 30 years of experience from both small and large deliveries within process instrumentation, we have the expertise and knowledge needed to deliver the right equipment for each individual assignment.

Flow-Teknikk AS was started in 1982 by Helge Bjørhall and is today one of the leading companies for the supply of process instruments to industry, research, and offshore in Norway. Our delivery program includes, among other things, instruments for measuring and regulating gases, liquids, levels, and pressure, as well as analysis instruments for pH, conductivity, and oxygen.

The Products of Flow – Teknik

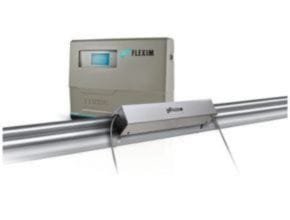

CLAMP-ON ULTRALYD FLOWMETERS

Flow-Teknikk har lang tradisjon med clamp-on ultralyd og var den første som introduserte dette på markedet i Norge. I dag representerer vi Flexim GmbH i Norge som er markedsleder og teknologileder innen clamp-on ultralyd mengdemåling.Vi har referanser i veldig mange ulike bransjer med clamp-on flowmeter noe som nok skyldes det allsidige naturen av måleprinsippet.

CORIOLIS FLOWMETERS

Coriolis flowmeter blant de mest avanserte og nøyaktige mengdemålerne vi leverer. De kan måle masseflow, volumflow, og tetthet av både væske og gass. Dette sørger også for at målerne vil kompensere for endringer i trykk og temperatur ved måling av gass.Hver coriolismåler har ett eller flere målerør som svinger ved hjelp av en spenningsfrekvens.

Når mediet strømmer i målerøret vil svingningene få ytterligere vridning på grunn av mediets treghet. To sensorer registrerer denne endringen av rørets vibrasjon i tid og rom som en faseforskjell. Denne forskjellen er en direkte måleverdi for masseflow. Ut fra målerørets vibrasjonsfrekvens kan man også måle mediets tetthet.

ELECTROMAGNETIC FLOW METERS

Electromagnetic flowmeters are among the most commonly used flowmeters for water and other media with good conductivity. In Flow-Teknikk, we supply 3 different series of electromagnetic flowmeters. The flow meters have been used by the industry for over 60 years, and are a well-known and accurate technology.

The meters require little maintenance and have little pressure drop. This leads to cost savings for the customer. Our suppliers supply mag meters in almost all sizes so that it is easy to find the right application.

From Tecfluid, we deliver our financial model with good accuracy and repeatability. From Heinrichs, we supply high-quality meters for more demanding applications. Our latest flowmeter MIS series from KOBOLD has been developed to be cost-effective, while at the same time being a modern, accurate, and intuitive meter.

INDICATORS

Flow-Teknikk supplies several different indicators for displaying process conditions, such as quantity, pressure, and temperature. In order to keep a demanding industrial process under control, it is important to know what the physical conditions are. That’s why we offer indicators for displaying flow rates that can be connected to almost all types of flowmeters.

We have various indicators that depend on what you are going to measure and which type of flowmeter you have. the indicators can have inputs for digital (pulse) or analog signals. Each individual indicator can be easily programmed in relation to the flow factor/output signal from the flow meter. The displays show the current quantity and total accumulated quantity (counter) in freely programmable quantity units. They can be supplied for battery operation or intended for voltage supply.

PROCESS SWITCHES

Flow-Teknikk emphasizes good product quality and therefore supplies safety switches from United Electric Controls. They specialize in the production of switches for temperature and pressure in pipes and containers.

The products are known for their high reliability, which is important in processes where abnormal pressures and temperatures must be recorded immediately. Read more about our safety switches from United Electric Controls below. We supply over 5,000 different types, models, and variants of safety switches. With this, you can be sure that the switch covers all necessary monitoring so that your applications are secure.

PRESSURE TRANSMITTERS

pressure transmitter is used to measure pressure changes in a piping system or to measure the level in an open / non-pressurized tank. Pressure transmitters help you keep the pressure or level in demanding industrial processes under control. An important factor in pressure measurement is temperature changes. Temperature changes can affect pressure measurements, but our pressure transmitters have integrated compensation for temperature fluctuations.

The pressure measurement takes place by the process of medium pressing against a membrane inside the transmitter. Pressure transmitters can also be supplied with so-called Diaphragm Seals. That is, the pressure membrane against the process is separated from the transmitter and connected to it via a capillary tube that is hermetically sealed and liquid-filled with a type of oil.

The process pressure propagates via the oil in the capillary hose to the transmitter. Used e.g. where you have high process temperatures, large vibrations, tough applications, level measurement, or where you want a larger membrane against the process.

Diaphragm Seals are available in many sizes and varieties. A variant of pressure transmitters is submersible transmitters, so-called Hydrostatic Level Probes. These are transmitters that have enclosure IP 68 and are immersed in a liquid to measure the liquid height (level). They are vented to the atmosphere via a thin hose. See Level / Pressure.

DP CELLS

A DP cell is used to measure a differential pressure across an element or a difference between 2 levels. The DP cell works by separating two pressure chambers, low pressure (LP) and high pressure (HP) by a continuous membrane. The DP cell compares two pressures: One coming through port A and one coming through port B. When the pressure in one chamber increases, the membrane will move toward the other chamber, and vice versa.

Typical applications are to measure the differential pressure across a diaphragm for flow measurement. Measuring the differential pressure across a pump or some form of constriction, or as a level measurement in a tank. An advantage of the DP cell is that it is equally suitable for open and closed tanks for level regulation. We have several different DP cells that may suit your application.

PRESSURE REGULATORS

We offer digital pressure regulators and pressure transmitters from Bronkhorst. Our pressure regulators can be used for both gas and liquid and measure either bar a, bar g, or differential pressure. The instruments have a piezoresistive pressure sensor. We also offer different control valves to be able to adapt the instrument to the application in question.

Mainly, we can control back pressure, forward pressure, or control the entire process loop. The controllers are delivered in 4 different series. El-press for laboratory and research, IN-Press for industrial applications, Metal-sealed for high purity, and IQ+ for ultra-compact design. The pressure regulators also have all communication options, such as 4-20mA Modbus, Profibus, and more.

RADAR LEVEL GAUGES

Radar level transmitter for precise and stable measurement of level and point measurement. Works on most liquids, including oil.Regardless of changed process conditions such as conductivity, temperature, pressure, etc.

APR-2000AL

The APR-2000AL/Profibus PA transmitter is applicable to for the measurement of differential pressure of gases, vapors, and liquids. The active element is a piezoresistive silicon sensor separated from the medium by separating diaphragms and specially selected types of manometric fluid. The special design of the active sensing element gives the element the pressure overload impact strength of up to 250 or 320 bar.

The transmitter electronic system performs the digital processing of measurement and generates the output signal with the communication module according to Profibus PA standard. The transmitter function performance is based on profile 3.0 of the Profibus PA standard.

Source : www.flow.no

Read More Articles :

- TC Fluid Control level measurement

- Tival Sensors TS-KNG Joint Lever Transmitter

- Tival Sensors TS-KFA 2 Level detection Sensor

- External Non-Contact Ultrasonic Level Sensor

- Omnitrol 621/721 Control Switches Lead Displacers

- ABB Magnetostrictive Level Transmitter LMT100

- ABB Process Master FEP630 Electromagnetic Flow Meter