Description

Gas Booster Single Stage – Single Acting Double Head SC Hydraulic is a leading manufacturer and designer of an ever-growing line of high-pressure, air-driven liquid pumps, as well as air and gas boosters which are being used in a variety of industries and applications. Growing since 1953, we offer liquid pressures as high as 65,000 psig and can exceed 17,000 psig in gas pressures.

General Product Information

- Requires No Lubrication

- Low Flow, Medium Pressure

- Remote Control Capabilities

- Oil-free High Pressure Section

- Nominal Pressures Up To 15,000-psi

- Air Operated – Does Not Require Electricity

This series has the same characteristics of the standard GB Series however the double head allows half the input pressure to achieve the same outlet pressure.

Gas Booster Single Stage – Single Acting Double Head Application

- Laser Cutting

- Leak Detection

- Pressure Testing Vessels

- Low Pressure Gas Recovery

- Charging Of Nitrogen Bottles

- Gas Assisted Injection Molding

- Aircraft Slide Chute Gas Storage

- Charging Of Nitrogen Accumulators

- Transfer Of Sf6 For Arc Suppression

- Transfer Of Sf6 For Circuit Breaker Insulation

- Boosting Pressure From Nitrogen Generators

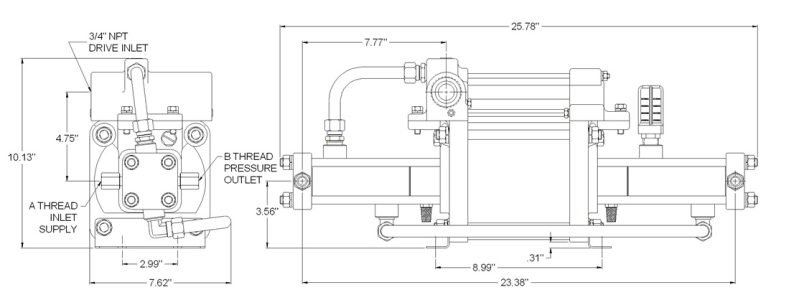

Dimensions

| Model No. | Maximum Material Rated Gas Supply Pressure (Ps) | Maximum Material Rated Gas Outlet Pressure (Po) | A Inlet Port B Outlet Port | Static Outlet Stall Pressure | Minimum Inlet Gas Pressure (Ps) | Displacement Per Stroke (in3 per cycle) |

| GB-D30 | 6,000 | 9,000 | 1/4″ NPT | 60 Pa | 200 psig (13 bar) | 3.1 |

| 410 bar | 620 bar | 1/4″ NPT | ||||

| GB-D75 | 6,000 | 20,000 psig | 9/16″-18 (1) | 150 Pa | 250 psig (17 bar) | 1.2 |

| 410 bar | 1,380 bar | 9/16″-18 (1) |

- Coned and threaded high pressure connection for 1/4″ O.D. tubing.

- Maximum allowed working pressure for oxygen service boosters: 5,000-psi max.

- Maximum allowed working pressure for hydrogen service boosters: 6,000-psi max.

- Oxygen & hydrogen service boosters not available on all models. Contact factory for more information.

Refer to corresponding gas booster performance curve for operating pressures. Maximum material rated outlet pressures can be reached under special operating conditions. Do not use air drive and/or gas supply pressures that equate to higher outlet pressures than those “maximum material rated outlet pressures” shown on table. Refer to Static Outlet Stall Pressure formula shown on table (for example, for gas booster model GBD-30 the formula is: Static Outlet Stall Pressure = 30*Pa+Ps). Maximum recommended air drive operating pressure: 100-psi. Maximum rated air drive pressure: 150-psi (only for static outlet stall pressure).

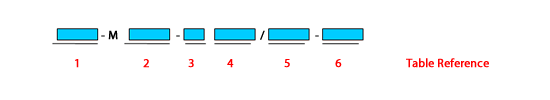

Gas Booster Single Stage – Single Acting Double Head SC Hydraulic Engineering Ordering

Gas Booster Series (1)

GB : Single Stage

No Modification

M402 : Remote Pilot

Cylinder Modification

D : Double Head

Pressure Ratio Single or First Stage

- 15 : GB

- 30 : GB

- 75 : GB

Pressure Ratio Second Stage

Blank : N/A on GB=D Series

Cylinder Modification

- Standard

- 02 : Oxygen Service (2)

- H2 : Hydrogen Service (2)

Notes:

- Do not fill gap on a two digit description

- Not available on GBD-D75, GBT-D15/75 and GBT-D30/75 models. Contact factory for more information.

Gas Booster Single Stage – Single Acting Double Head Modification

Performance Chart

M014 – Counter Port: This option provides a 5/8-18-UNF thread port on the air motor section of the pump for installing a mechanical cycle counter.

M402 – Remote Pilot: This option provides a 1/8” NPT female port for remotely controlling the start/stop of the pump by connecting an external air signal to actuate the air cycling valve.

Source: schydraulic.com

Read more :