Descriptions

SC Hydraulic Engineering L3 Compact Liquid Pumps is a leading manufacturer and designer of an ever growing line of high pressure, air-driven liquid pumps, as well as air and gas boosters which are being used in a variety of industries and applications.

Growing since 1953, we offer liquid pressures as high as 65,000 psig and can exceed 17,000 psig in gas pressures.

Product Information

- PORTABLE

- ECONOMICAL

- LIGHTWEIGHT

- REQUIRES NO LUBRICATION

- EASY TO INSTALL & OPERATE

- IDEAL FOR OEM APPLICATIONS

SC air driven compact liquid pumps operate on the principal of differential areas. An air piston drives a smaller diameter hydraulic plunger to provide a pressure ratio. The pressure ratio determines the maximum outlet pressure.

SC compact liquid pumps cycle automatically. When compressed air is first applied to the pump, it will cycle at its maximum speed producing maximum flow. At this stage, the pump is acting as a transfer pump filling the pressure receiver with liquid. The pump will then gradually start to cycle at a slower rate as the pressure in the receiver increases and offers more resistance to the reciprocating differential piston.

SC pumps stop automatically when the output pressure force and the air drive force is balanced to create a stall condition. At this point, the pump will maintain pressure without energy consumption, thus providing an economical source for hydraulic power.

SC pumps will cycle with a slight drop in the outlet pressure or increase in the air drive pressure due to very low frictional resistance.

SC pumps are suitable for use on scissor jack lifts, aircraft jacks, clamping devices, punches and pin presses, valve actuation, roller tensioning, torque wrenches, press system overload, pressure testing, crimping, trash compactors, paper and printing paper cutters.

Compatible with all hydraulic fluids, plain water, distilled and di-ionized water, solvents, mild chemicals and liquefied CO2.

316 Stainless steel wetted hydraulic construction, light weight (six pounds), 3.5″ x 7.00″ body includes inlet and exhaust muffler.

Available in eight ratios: 15, 25, 35, 45, 65, 105, 125 and 195.

Requires less than 15 psi air drive pressure to operate, the L3 series pump is self priming for immediate operation. Maximum air drive pressure is 125 psi (intermittent duty)

Can supply pressures up to 24,375 psi @ 125 psi air drive and flow rates up to 1.0 gpm.

Requires no electrical power or connections.

Alternative gases that can drive the pump include nitrogen vapor from liquefied gas or natural gas pipeline, thus offering a completely self-contained package independent of external power sources.

Hand pump attachment option allows for manual operation when shop air is not available or for precision pressure control.

Application

- Crimping

- Valve actuation

- Pressure testing

- Torque wrenches

- Clamping devices

- Trash compactors

- Well Control Panels

- Press system overload

- Punches and pin presses

- Roller and bolt tensioning

- Scissor jack lifts, aircraft jacks

Dimensions

| Dash | Actual | Max Pressure | Displacement | NPT/LF4 (Std) | SAE/LF4 (Optional) | C | D | L | |||

| Number | Ratio | psig @125 Pa (1) | Per Cycle | A Thread | B Thread | A Thread | B Thread | B Thread | |||

| Cu. In. | |||||||||||

| -15 | 20 | 2,25 | 0.27 | 3/8″ | 1/4″ | -8 SAE | -6 SAE | 7/16-20 * | 1.5 | 2.43 | 8.02 |

| -25 | 31 | 3,5 | 0.18 | 3/8″ | 1/4″ | -8 SAE | -6 SAE | 7/16-20 * | 1.5 | 2.43 | 8.02 |

| -35 | 40 | 4,375 | 0.14 | 3/8″ | 1/4″ | -8 SAE | -6 SAE | 7/16-20 * | 1.5 | 2.43 | 8.02 |

| -45 | 55 | 6,125 | 0.1 | 3/8″ | 1/4″ | -8 SAE | -6 SAE | 7/16-20 * | 1.5 | 2.43 | 8.02 |

| -65 | 79 | 8,875 | 0.069 | 1/4″ | 1/4″ | -6 SAE | -6 SAE | 7/16-20 * | 1 | 1.93 | 7.52 |

| -105 | 123 | 14 | 0.044 | 1/4″ | 1/4″ | -6 SAE | -6 SAE | 7/16-20 * | 1 | 1.93 | 7.52 |

| -125 | 138 | 15,6 | 0.044 | 1/4″ | 7/16-20 * | -6 SAE | – | – | 1 | 1.93 | 7.52 |

| -195 | 213 | 24,375 | 0.038 | 3/8″ | 9/16-18 | – | – | – | 2.24 | 2.71 | 8.75 |

Ordering

| TABLE 1 | Gas Booster Series (1) | ||

| GB | Single Stage | ||

| TABLE 2 | Modification | ||

| Blank | No Modification | ||

| M402 | Remote Pilot | ||

| 3 | EPR O-rings, Polyurethane Main Seal | ||

| TABLE 3 | Cylinder Modification | ||

| Blank | Single Head | ||

| TABLE 4 | Pressure Ratio Single or First Stage | ||

| 5 | GB | ||

| 15 | GB | ||

| 30 | GB | ||

| 75 | GB | ||

| TABLE 5 | Pressure Ratio Second Stage | ||

| Blank | N/A on GB Series | ||

| TABLE 6 | Service Option | ||

| Blank | Standard | ||

| 2 | Oxygen Service (2) | ||

| H2 | Hydrogen Service (2) | ||

| Notes : | (1) Do not fill gap on a two digit description | ||

| (2) Not available on GBD-D75, GBT-D15/75 and GBT-D30/75 models. Contact factory for more information. | |||

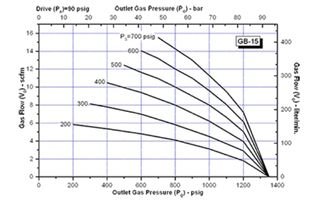

Performance Chart

Modification

M002 – Remote Pilot: This option provides for a separate 1/8″ NPT external air to pilot cycling valve. Useful for remote control operation of the pump.

M003 – Straight Threads: The straight thread modification offers the fluid inlet and outlet ports with SAE straight thread options.

M004 & M027 – Integral Hand Pump Attachment: This modification permits supplementary operation of the pump by hand. Useful in precise testing or emergency back-up applications requiring a hand pump in addition to pneumatic power.M005 – Distance Piece: The distance piece models are furnished with an isolator attachment which prevents the hydraulic piston from retracting into the air drive during operation, thus providing 100% separation of the hydraulic assembly from the air drive assembly. The isolator attachment prevents contamination and acts as a heat barrier.

M006 – No Air Piston Return Spring: This modification provides improved fill on the suction stroke when pumping liquefied gases such as CO2.M008 – Noise Reduction: Noise reduction incorporates a special internal bumper allowing the pump to run quieter without impairing performance.M009 – 1/4″ O.D. High Pressure Tubing Fluid Outlet: This modification provides a coned and threaded high pressure connection for 20 KSI 1/4″ O.D. tubing (7/16-20 thread LF4 connection).M011 – Mounting Holes: Tapped and threaded bottom mounting holes are available for tank top mounting applications.

Read more :

- SC Hydraulic Engineering GB Series Gas Booster Single Stage

- SC Hydraulic Engineering 10-4 air driven Liquid Pump

- SC Hydraulic Engineering D6 & 10-6 Liquid Pump

- SC Hydraulic Engineering 80-5 Intensifiers

- SC Hydraulic Engineering GB Series Gas Booster Single Stage

- SC Hydraulic Engineering GB-D Series Gas Booster Single Stage

- Gas Booster Single Stage Double Acting SC Hydraulic Engineering