Automated Chuck Change System

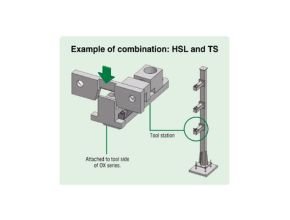

Chuck automatic exchange is effective for the reduction of setup change time, different connection of air and electrical components, as well as location accuracy for end of arm tooling exchanges. The tool station can be either a tree-type floor stand or attached to the traverse axis (NT type). Magnet chuck hangers use the magnetic power of neodymium to hold the end of arm tooling.

The Product For Automated Chuck Change System :

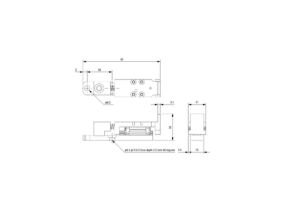

Auto Quick Chuck Change Hanger 3Kg

Automated chuck change can be performed in different ways. In this case the EOAT is literally hung on the station side, which is HSL. Weight capacity is 3Kg. Please check TS for the tool side.

Specification

| Weight | 182 g |

|---|---|

| Load (Kg) | 3 |

| Side | Station |

| Item | HSL |

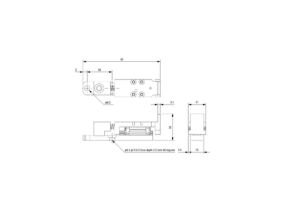

Hanger Tool 3Kg

Automated chuck change can be performed in different ways. In this case, TS on the EOAT is literally hung on the station side. Weight capacity is 3Kg. Please check HSL for the station side.

Specification

| Weight | 43 g |

|---|---|

| Load (Kg) | 3 |

| Pag | ‘1-33 |

| Side | Tool |

| Item | TS |

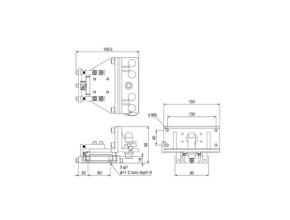

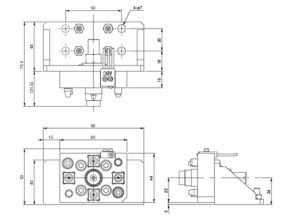

Auto Quick Chuck Change Hanger 35Kg

Automated chuck change can be performed in different ways. In this case the hole on the tool side fits the shaft on the station side, which is HLAL. Weight capacity is 35Kg. Please check TLA1 for the tool side.

Specification

| Weight | 2800 g |

|---|---|

| Load (Kg) | 35 |

| Side | Station |

| Item | HLAL |

Neo Chuck Hanger (Fixed Side) 1Kg

Automated chuck change can be performed in different ways. In this case the magnetic power of neodymium is used to attach the EOAT to the station side, which is HNE-48. Weight capacity is 1Kg. Please check TNE-48I for the tool side.

Specification

| Weight | 540 g |

|---|---|

| Load (Kg) | 1 |

| Side | Station |

| Item | HNE-48 |

Source : eins1.eu

Read More Articles :