Overview

The special design of the Kem Kupper GFM High Resolution series flow meters is tailored for measuring and dosing extremely small quantities. They are ideal as meters in test stands and for applications where great flexibility with optimum measuring performance is in demand. Lubricating as well as non-lubricating, abrasive, aggressive and filled media across a very broad viscosity range can be measured precisely and reliably.

The innovative Kem Kupper GFM High Resolution flow meters combine the absolute measuring precision of proven gear flow meters with exceptionally high resolution, compact, integrated electronics. The precise mechanical measuring element supports the most dynamic possible measuring range with the lowest possible activation point. Extraordinarily broad measuring ranges are realized and cascading fades into the background. The GFM High Resolution is therefore suitable for cost-reducing system designs and minimizes replacement part inventories.

Only high-grade steels and alloys that even withstand corrosive liquids are used in the production of GFM High Resolution flow meters. Combined with the use of tungsten carbide bearings, the GFM High Resolution guarantees optimum measurement accuracy and a long service life under even the toughest application conditions.

Stainless steel bearings guarantee smooth start-up behavior, even with very small volume flows and low-viscosity media. The combination of various gear dimensions and modules allows a wide range of sizes that can cover a huge measuring range

Principle and Design

GFM High Resolution flow meters are positive displacement meters. Two precise gears rotate freely inside the measuring chamber.

Sealed cavities are created between the gears and the housing. The measured media causes the rotation of the gears. The flowing medium is distributed evenly in the measuring chamber and causes the rotation of the gears. The gear wheels rotate freely and undamped in the media flow. Their rotational frequency is proportional to the flow rate and is measured by non-intrusive sensors (pickups) through the housing wall.

A variable magnetic field is generated in addition on the rotating gear, and is recognized and evaluated by a high-resolution hall element. Concrete resolutions up to 1,000,000 Imp/l can be generated from this through interpolation. The flow direction of the medium can also be derived and output.

Pulses per unit of volume are available for analysis. The calibration factor (K-factor) of the flow meter describes the exact pulse rate per unit of volume. In order to determine the individual calibration factor of a flow meter, we calibrate each of our meters in house prior to delivery. The operating viscosity specified by the customer is taken into account for calibration. A corresponding calibration certificate is included with every flow meter we supply.

The GFM High Resolution meters from KEM are suitable for accurate measurement of different liquids with viscosities of approximately 1 to 25,000 mm²/s. For low-viscosity media and fuels gear flow meters with ball bearings and reduced tolerances are used. Precisely measuring abrasive media is no problem thanks to highly robust tungsten carbide bearings.

Due to the high output frequency, good resolving capacity, and short response times, our GFM High Resolution flow meters are ideal for measuring very small quantities and suited for applications in dosing systems, test stands, and for all types of consumption measurement.

Features

Applications

- Test stand applications

- Dosing of extremely small quantities

- Consumption monitoring and additive dosing

- Coating and PU applications

- Monitoring of dosing pumps and operating materials

Media

- Adhesives and sealants

- Paints and coatings

- Additives and catalysts

- Lubricants and preservatives

- Fuels and operating fluids

Features

- Measuring range up to 1:1000

- Extreme resolution up to 1,000,000 Imp/l

- Compact, integrated electronics

- Output signal for flow and direction

- High measuring accuracy up to ±0.1 %1) Exceptional repeatability of ±0.05 %

- Short response times Pressure-resistant up to 250 bar [3,625 psi]

- Medium temperature up to 125 °C [257 °F]

- Explosion protection for Zone 2

GFM Series

GFM High Resolution flow meters are offered in two different series, differentiated mainly by the structure of the measuring kit.

Series A is equipped with high quality tungsten carbide bearings. These flow meters are especially well suited for measuring non-lubricating and abrasive media. Since tungsten carbide withstands abrasive media, reliable applications with extremely aggressive media are possible. Even highly filled media can be measured well with the A-series GFM High Resolution flow meters. Thanks to the finest tolerances, their penetration into the bearings is extremely limited and they have no negative impact on the start-up behavior and friction in the measuring kit.

Series B distinguishes itself through the use of high-precision stainless steel ball bearings and optimized tolerances of the measuring kit. These flow meters are used primarily for measuring clean, lubricating media. The ball bearings ensure minimum friction in the measuring kit. This makes it possible to realize extremely low activation points that are expressed in a very broad measuring range. Optimized tolerances minimize the internal leakage in the GFM High Resolution, so that the specified measuring accuracy can also be guaranteed for low-viscosity media.

In order to obtain the most accurate measured values, series A should be installed as vertically and series B as horizontally as possible.

Specifications

Technical Data

| Measuring Accuracy | Up to ±0.1 %3 |

| Repeatability | ±0.05 % (under the same conditions) |

| Deviating in the extended measuring range | |

| Materials | Housing: as per DIN 1.4305 [AISI 303], 1.4404 [AISI 316L], Aluminum (EN 7075) |

| Gears: as per DIN 1.4122, 1.4501 [AISI F55] | |

| Bearing/Axis: Tungsten carbide or stainless steel ball bearing | |

| Seals: FKM, PTFE | |

| Dimensions | See dimensional drawing (page 5 of datasheet) |

Technical Data – Electronics

| Electrical Output | Push-Pull, I max 20 mA |

| Supply Voltage | 7 – 30 V DC |

| Quiescent Current | < 20 mA |

| Ambient Temperature | -40 °C up to +70 °C [-40 °F up to +158 °F] |

| Medium Temperature | non Ex: -40 °C up to +125 °C [-40 °F up to +257 °F] |

| Ex, Zone 2: -40 °C up to +70 °C [-40 °F up to +158 °F] | |

| Ingress Protection | IP66 |

| Ex Protection | Zone 2: II 3G Ex nA IIC T4 Gc |

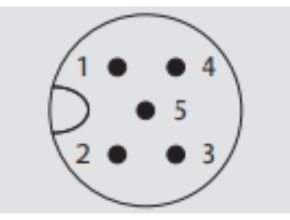

| Electrical Connection | 5-pin plug M12; A coded |

| 1 = +UB | |

| 2 = signal for direction | |

| |

| 3 = 0 V | |

| 4 = frequency signal for flow | |

| 5 = n.c. |

Download Datasheet: GFM High-Resolution Kem Kupper Gear Flow Meter

Reference: www.kem-kueppers.com

Other Articles :

- GFM Mass Flow Meters

- Kem Kuppers Evaluation Electronics and Additional Accessories

- Dwyer GFM Series Gas Mass Flow Meter & Controllers

- HM F Series Kem Kuppers Turbine Flow Meter

- Kem Kuppers Pickups and Amplifiers