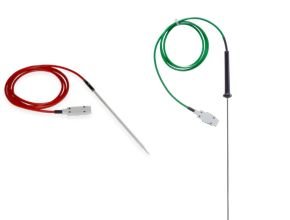

ELECTRICAL CABLE SENSORS

Electrical temperature sensors are used in numerous industrial processes to measure temperatures. Possible applications can be found in a wide variety of industrial processes, laboratory and medical applications and in the pharmaceutical sector. Ludwig Schneider is a manufacturer of electrical probes and offers thermocouples and resistance thermometers as well as other precision measuring instruments. With our many years of experience and expertise, we are able to offer individual solutions for customers from various industries. We are characterized by flexibility and high quality in all batch sizes: Whether individual production, small or large series.

Of decisive importance is the use of electrical probes wherever the measured value acquisition takes place remotely from the visualization or the measured value processing. Thanks to the exploitation of internal synergy effects we are also able to manufacture special probes made of glass – in addition to electrical probes made of stainless steel, brass and Inconel. These are required in particular within laboratory applications.

THERMOCOUPLES

Thermocouples are based on the thermoelectric effect and are characterized by their robust design and an excellent volume/temperature range relationship. Please take into account, however, the higher temperature tolerance classes and the increased installation work. We manufacture screw-in, immersion, insertion and surface probes with application specific probe tips. Our range also includes different head transmitters with measuring inserts and protective tubes as well as special versions.

OVERVIEW OF THE DIFFERENT THERMOCOUPLE TYPES

| Type | Materials | Temperature range |

|---|---|---|

| Type T – Cu/CuNi | Copper/Constantan | -270 °C to +400 °C |

| Type J – Fe/CuNi | Iron/Constantan | -210 °C to +1200 °C |

| Type E – NiCr/CuNi | Nickel chrome/constantan | -270 °C to +1000 °C |

| Type K – NiCr/Ni | Nickel chrome/nickel | -270 °C to +1372 °C |

| Type N – NiCrSi/NiSi | Nicrosil/Nisil | -270 °C to +1300 °C |

| Type S – Pt10Rh/Pt | Platinum Rhodium/Platinum | 0 °C to +1482 °C |

| Type R – Pt13Rh/Pt | Platinum Rhodium/Platinum | 0 °C to +1482 °C |

| Type B – Pt30Rh/Pt6Rh | Platinum rhodium/platinum rhodium | 0 °C to +1820 °C |

RESISTANCE THERMOMETER PT100 MANUFACTURER

Resistance thermometers are manufactured and used today in a countless variety of designs. The construction of a resistance thermometer is basically characterized by a measuring resistor, a corresponding housing and the required connection possibility. The DIN 43772 standard defines only a very small number of designs, in which the components and dimensions are specified. The standardized resistance thermometers always consist of a connection head, a protection tube and an exchangeable measuring insert and can be assembled in a modular way.

MODE OF OPERATION RESISTANCE THERMOMETER PT100

The measuring resistor is connected to a constant measuring current. The resistor generates a voltage drop which is measured. This voltage drop can be derived directly from Ohm’s law:

U = R – I U = voltage in V, R = resistance in ?, I = current in A

The measuring voltage must be transmitted as unaltered as possible to the place of evaluation or display. Especially due to the transmission in 2-wire circuit, the additional line resistance leads to an increase of the total resistance and thus inevitably to measurement errors. To prevent the measuring resistor from heating up due to the measuring current, it should be selected as small as possible. It can be assumed that a measuring current of ? 1 mA causes negligible self-heating in the measuring resistor.

TECHNICAL DATA, PRODUCT VARIANTS AND ACCESSORIES

| FEATURE | VARIANTS |

|---|---|

| Measuring range | -196 °C … 600 °C (at tolerance class B) |

| Tolerance class | B / A / AA (1/?3B) / 1/?10B |

| Material | Stainless steel, Inconel, brass or glass |

| Diameter | From ø 1,6 mm available |

| Variants | Mit Eintauch- oder Einstechspitze |

| Accessories | ThermowellsDifferent connection heads Head transmitter, programmable Measuring inserts Stop flange fittings |

Source: www.ludwig-schneider.de/en/