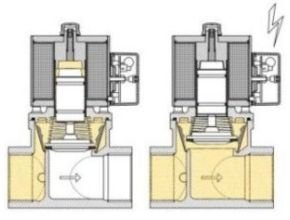

Safety solenoid valves slow opening and fast closing

Delta Elektrogas VML Safety Solenoid Valve is a safety valve that is normally closed, with a fast or slow opening and an adjustable rapid section for initial gas flow. When not in the working position the spring works on the disc keeping the gas passage closed.

When the coil is powered the valve opens rapidly in the first section of the flow, then slowly, with adjustable speed. When power is switched off the valve rapidly shuts.

Delta Elektrogas VML Valve of the device is suitable for gas and air blocking and adjusting controls in atmospheric burners or fan-assisted burners, in industrial kilns, and in all gas equipment that uses gas solenoid valves (qualified for continuous service – 100% ED).

Baca juga: Elektrogas automatic safety solenoid valves

Function and Application

Delta elektrogas VMR type valve is a safety shutting device that uses an auxiliary power supply. When it is de-energized, the spring pushes on the seal disc, keeping the gas passage closed. Now, the inlet chamber is under the gas line pressure which forces on the disc, increasing the closing function and improving the seal.

When the coil is powered the valve opens rapidly, against the strength of the spring and gas pressure. The flow may be adjusted using the regulating screw on the top (see the installation and service instructions). If the power supply is shut off, the valve rapidly closes, interrupting the gas flow

Specification

- Connections

- Internal threaded ISO 7-1 from Rp3/8 to Rp2½

- ANSI-ASME B1.20 from 3/8” NPT to 2”½NPT

- Flanged ISO 7005 PN16 from DN40 to DN80

- ANSI-ASA-ASME B16.5 class 150 from 2” to 6”

- Voltage ratings 230 VAC 50/60 Hz

- 120 VAC 50/60 Hz

- 110 VAC 50/60 Hz

- 24 VAC/DC

- Voltage tolerance -15% to +10%

- Temperature -15°C to +60°C (+5°F to +140°F)

- Max. operating pressure 200 mbar (3 psig)

- 360 mbar (5 psig)

- 500 mbar (7 psig)

- 6 bar * (90 psig)

- Body test pressure

- 1 bar (15 psig)

- 9 bar * (130 psig)

- Closing time < 1 second

- Opening time Adjustable

- Gas strainer 600 µm (0.02 in), metal mesh (except 6 bar models)

- Enclosure IP54 (NEMA 3), optional IP65 with cable (NEMA 4)

- Cable gland

- M20x1,5 for terminal box

- PG 9 for ISO plug

- Wires cross-section

- 2,5 mm2 max. (AWG 12) for terminal board

- 1,5 mm2 max. (AWG 14) for ISO plug

- Electrical Safety Class I (EN 60335-1)

- Coil winding insulation Class H (200°C, 392°F)

- Coil thermal resistance Class F (155°C, 311°F)

Data Sheet Elektrogas-VML

Other Article:

- Delta Elektrogas – VMRNA Automatic Vent Valve for Gas

- Elektrogas VMR60 Solenoid gas control valve

- Delta Elektrogas LMV Linear Control Valve

- Delta Elektrogas R-RS -100 Medium Pressure Gas Regulators

- Delta Elektrogas EVRMNC EVRM6NC Safety Valve For gas

- VM2V S4 Bamo Manually Operated 2-Way Ball Valves

- VM2V M1 Bamo Manually Operated 2-Way Ball Valves

- Delta Elektrogas Combustion Safety and Control

- Delta Elektrogas LD, LDM Tightness Control Device

- Delta Elektrogas RAG Gas Pressure Regulators

- Delta Elektrogas RFS Gas Pressure Regulators

- Delta Elektrogas VMM Multiple Safety Solenoid Valve