Introduction

HONDA ELECTRONICS has brought innovations to the world by introducing ultrasonic technologies since the release of the world-first transistor fishfinder in 1956. With originality in mind, HONDA ELECTRONICS also respects technologies in various fields and participates in many collaborative projects. This “Open Technology” policy shall lead us to make further contributions that will enhance human life.

Honda Ultrasonic Sensor are applying our ultrasonic research to a variety of fields within the industrial equipment sector.

Cleaners(Ultrasonic washers), machining tools(ultrasonic welders), measuring equipment, flow meter, and so forth, have proven their use under various conditions. And new applications in the areas of ultrasonic reactor(maturity)and power dynamics(motors) hold great promise for future success.

Our Industrial Instruments Division works with over 500 ultrasonic elemental technologies to develop and market state-of-the-art products. And in joint research with clients in a variety of fields, we are furthering our goals by designing the industrial instruments of tomorrow.

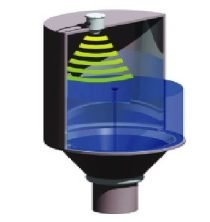

Principle

Ultrasonic waves transmitted from the sensor are reflected back from the measured object, and the distance is calculated based on

the echo return time. This makes it possible to perform operations such as measuring the liquid level inside a tank, or monitoring the

remaining amount of materials in a tank.

- Distance = Speed of sound × Time

The distance to the measured surface is calculated based on the speed of sound and the time elapsed between the transmission of

the signal and the return of the echo. The distance to the bottom of the tank is set in advance, so that the amount of liquid remaining

in the tank can be calculated.

Advantages

Levels can be monitored without any contact with the materials that are measured. Levels can be monitored continuously, even under HD duty conditions.

Honda Ultrasonic Level Meter Product

- HD320 series | Ultrasonic Level Meter

Compact, light weight level meter which include sensor and display in one unit. Graphical display shows real time wave form in A-mode and it is useful for maintenance. Mask function can avoid noise interference.

Features

- Two-wire interface can suppress the cost of installation, wiring and operation.

- Two-wire system supplies electric power through the data line. Electrical wiring is completed only with two lines, power + data and ground.

- Four screen mode can be selected

- Large display is adopted for HD323 (Display size : 50 x 25mm, 49% larger than HD320)

- Mask functio

- Unnecessary signal can be eliminated from the received signal by manually.

- Echo signal from existing structure positioned between sensor and target cause interference. Mask function removes these

- unnecessary echo effectively.

- Low-cost model with two-wire system, featuring a graphic LCD display

- Graphic LCD display shows the A-mode waveform

- When performing measurements, masking can be applied to objects positioned between the sensor and target

Main applications and usage examples

- Management of liquid level in tanks

- Management of sewage level inside pipes

- Measurement of water level in lakes, ponds, and rivers

| Model No. | HD320 | HD323 | |

| Number of channels | 1 | ||

| Frequency | 50kHz | ||

| Measurement target | liquid | ||

| Measurement distance range | 0.25 to 7.5m | ||

| Resolution | Measurement | 1mm | |

| Display | 1mm | ||

| Accuracy | ±0.25%F.S. | ||

| (±1.88cm) | |||

| Data update cycle | 10sec | ||

| Sensor directive angle (beam angle) | 14°(-6dB)?/?10°?-3dB) | ||

| Power source | Voltage | 24VDC | |

| Power consumption | 0.6W | ||

| Display | Graphic LCD | ||

| Display size | 28.1 x 9.1mm | 50 x 25mm | |

| Output | 4-20 mA current | Resolution: 12 bits | |

| (Max. load resistance 500? 24V) | |||

| Ambient operating temperature | -20 to 70? | ||

| Material | PP (polypropylene) | ||

| Protection | IP65 equivalent (without lid: IP20 equivalent) | ||

| Dimensions | dia. 93 x 110mm | ||

| Cable length | 10m | ||

| Weight | 350g | ||

| Mounting screw | G2 (PF2) | ||

* Do not use metal nut or metal flange. It may cause error on measurement.

* Please use nut or flange that made of plastic.

2. HD350 series | Ultrasonic Level Meter

Compact, light weight level meter which include sensor and display in one unit. Graphical display shows real time wave form in A-mode and it is useful for maintenance. Mask function can avoid noise interference.

Features

- For screen mode can be selected

- Large display is adopted for HD353-A (Display size : 50 x 25mm, 49% larger than HD350-A)

- Mask function

- Unnecessary signal can be eliminated from the received signal by manually.

- Echo signal from existing structure positioned between sensor and target cause interference.

- Mask function removes these unnecessary echo effectively.

- Interface

- Three interface methods are prepared for remote operation.

- RS-485 (MODBUS protocol)

- 4-20 ?A current output

- Contact points (relay output)

- Three interface methods are prepared for remote operation.

- Low-cost DSP level meter

- Graphic LCD display shows the A-mode waveform

- Wide measurement range, from 0.3 to 10 m

- When performing measurements, masking can be applied to objects positioned between the sensor and target

- Remote operation is enabled with RS-485 ( MODBUS® protocol ), 4 to 20 mA current output, and alarm output contact points

Main applications and usage examples

- Management of liquid/powder levels in tanks

- Measurement of water level in lakes, ponds, and rivers

Specification

| Model No. | HD350-A | HD353-A | |

| Number of channels | 1 | ||

| Frequency | 50kHz | ||

| Measurement target | liquid / powder | ||

| Measurement distance range (1/2 for powder) | 0.3 to 10m | ||

| Resolution | Measurement | 1mm | |

| Display | 1mm | ||

| Accuracy | ±0.25%F.S. | ||

| (±2.5cm) | |||

| Data update cycle | 0.5 sec | ||

| Sensor directive angle (beam angle) | 14°(-6dB)?/?10°?-3dB) | ||

| Power source | Voltage | 12 – 24 VDC ±10% | |

| Power consumption | 3 W | ||

| Display | Graphic LCD | ||

| Display size | 28.1 x 9.1mm | 50 x 25mm | |

| Output | Alarm output | 1 point each for upper/lower | |

| (NPN open collector) | |||

| 4-20 mA current | Resolution: 12 bits | ||

| (Max. load 500?) | |||

| Interface | RS-485 (Transmitting distance : max. 1200m) | ||

| Ambient operating temperature | -20 to 70? | ||

| Material | PP (polypropylene) | ||

| Protection | IP65 equivalent (without lid: IP20 equivalent) | ||

| Dimensions | dia. 93 x 110mm | ||

| Cable length | 10m | ||

| Weight | 350g | ||

| Mounting screw | G2 (PF2) | ||

? Option: 30m cable

* Do not use metal nut or metal flange. It may cause error on measurement.

* Please use nut or flange that made of plastic.

3. HD1200 | Ultrasonic Level meter

Advanced DSP technology enabled stable measurement.

Overview

- Advanced level sensing algorithm suppresses the noise level and artifacts and enabled stable measurement.

- One main unit handles two sensors at once. Two different types of sensors can be installed and each may measures different range.

- Data logging function to micro SD TM.

- Flow measurement by measuring catchment level is possible.

Equipped with DSP that achieves stable measurement

- A unique level detection algorithm is achieved with DSP, which enables stable measurement by eliminating the effects of noise and unwanted reflection

- Two sensors can be connected to the main unit at the same time, so measurement can be performed at two separate locations with different measurement ranges

- Log data can be stored on a micro SD™ card

- Standard-equipped with a weir type flow meter function ( open channel flow meter )

Main applications and usage examples

- Management of liquid/powder levels in tanks

- Measurement of water level in lakes, ponds, and rivers

- Weir type flow measurement

Specification

Level Ultrasonic Transmitter

| Model No. | HD1200 | |

| Channel | 2 | |

| Frequency | 10 to 60 kHz (select by sensor) | |

| Measurement object | liquid / powder | |

| Resolution | Measurement | 1 mm |

| display | 1 mm | |

| Accuracy | ±0.25%?F.S. | |

| Data refresh rate | 2 sec. approx. (depends on sensor) | |

| Power source | Voltage | 100 to 240 V AC?±10 % |

| Power consumption | 10 VA | |

| Display | LCD with backlight | |

| Output | Alarm | 4 points / channel |

| 250VAC, 5 A (relay contact) | ||

| 4-20mA current | Resolution: 1/4000 | |

| (Max. load resistance 600?) | ||

| Interface | RS-485 (max. distance: 1200 m or less) | |

| RS-232C (max. distance: 10 m or less) | ||

| Memory | microSDTM *1 | |

| Operation temperature | -20 to 70? | |

| Material | ABS | |

| Protection | IP66 equivalent | |

| Dimension (WxDxH mm) | 176?84?237 | |

| Weight | 1.8 kg | |

NOTE : Weir type flowmeter is available on CH1

*1 : microSDTM is a trademark of SD Card Association

Level Ultrasonic Sensor Specification

| Model No. | Sensor | |

| TS40-5 | TS40T-5 | |

| Frequency | 40 kHz | |

| Measurement range | 0.3 to 20? | 0.3 to 15m |

| (1/2 value for powder) | ||

| Directive angle | 12°(-6dB) | 22°(-6dB) |

| (half of full angle) | 8°(-3dB) | 16°(-3dB) |

| Operation temperature | -20 to 70? | |

| Material | Epoxy/silicone/ PP | PVDF |

| Protection | IP68 equivalent | IP68 equivalent |

| Dimension (mm) | dia. 84×90 | dia. 98×87 |

| Sensor cable length | 5m | |

| Weight | 500g | 860g |

| Mounting screw | R1 (PT1) | G1 (PF1) |

Note :

- TS40T-5 is chemical resistant.

- The sensors cannot be used in hydrofluoric acid environment.

4. HD500 series | Ultrasonic Level meter

measures liquid or chemical surface level with no contact by ultrasound.

Overview

- Hiring high frequency ultrasonic system enables small dead zone and is possible to measure short distance.

- High resolution, 0.1 mm

- Minimize the main unit and sensor unit, so easy to install to the limited area.

- Sensor part is chemical proof plastic (PFA).

- Equipped RS-232C interface, 4-20 mA current output, Alarm output allows to communicate with existing system.

- Flow measurement by measuring catchment level is possible.

Usage

- Sensing or positioning goods on production line

- Liquid level sensing in small size tank

Specification

| Model No. | HD500-C | HD500-D | |

| Number of channels | 1 | ||

| Frequency | 200 kHz | 400 kHz | |

| Measurement target | Liquid | ||

| Measurement distance range | 0.12 to 1.0 m | 0.06 to 0.45 m | |

| Resolution | Measurement | 0.1 mm | |

| Display | 0.1 mm | ||

| Accuracy | ±0.25 % F.S. | ±0.25 % F.S. | |

| (±0.25cm) | (±0.1cm) | ||

| Data update cycle | 0.05 seconds | ||

| Sensor directivity angle | 10° (-6dB) | 5° (-6dB) | |

| 7° (-3dB) | 4° (-3dB) | ||

| Power source | Voltage | 12 to 24 V DC ±15% | |

| Power consumption | 3 W (500mA when started) | ||

| Display | 4-digit LED | ||

| Output | Alarm | 2 points each for upper/lower | |

| 30V DC, 0.1 A (NPN open collector) | |||

| 4-20mA current output | Resolution:16bits | ||

| (Max. load resistance 450?? | |||

| Interface | RS-232C?Transmission distance : Max.10m) | ||

| Model | Main unit | Sensor unit |

| Ambient operating temperature | 0 to 50? | |

| Material | ABS | PFA |

| Cable: FEP | ||

| Capcon : PVDF | ||

| Capcon inner seal: PPE-V | ||

| Structure | IP43 equivalent | IP65 equivalent |

| Dimensions | 113?52.5?94 | dia 42?39 |

| (WxDxHmm) | ||

| Sensor cable length | – | 2 m |

| Max. sensor cable length | – | 2 m |

| Weight | 300 g | 150 g |

| Screw | – | M32 P1.0 |

Only HD500-C is standard-equipped with the weir type flowmeter function.

The flow rate can also be measured for triangular weir.

5. HL2000 | Ultrasonic Interface Level Meter

Overview

Measures the flying time of ultrasonic signal to the sludge level. Ultrasonic signal has characteristic that it reflects where the density changes. Submerged sensor transmit ultrasonic signal, then the signal reflects at the interface inside the tank. Some part of signal penetrate into the sludge and it also reflects at the rake or bottom of the tank. Ultrasonic signal transfers in the unclear water. There is no need to contact to the measuring object (sludge), the measurement can be done without sinking the sensor deep into the tank.

Features

- Measuring range is wide from 0.5 to 10 meters.

- One unit can measure two distances from different sensors.

- Thanks to ultrasonic signal, no need to care about clarity of the water, day or night (nob need of light)

- Calculation process is prepared for supply water quality or deposited sludge, so no need of extra setting or calibration.

- Durable and stable. Both main unit and sensor unit does not consist any mechanical movement part.

Usage

- Interface management of settling tank at industrial wastewater treatment facility

- Interface management for a settling tank at sewage treatment facility

Specification

| Model No. | HL2000 | |

| Number of channels | 2 | |

| Frequency | 400 kHz | |

| Measuring target | Sludge interface | |

| Measurement distance range | 0.4 – 10 m | |

| Resolution | Measurement | 1 cm |

| Display | 1 cm | |

| Data update cycle | 1 sec. | |

| Sensor directivity angle (half of full angle of sound pressure) | 6° | |

| Power source | Voltage | 100-240 V AC ±15% |

| Power consumption | 10 VA | |

| Display | LCD (with backlight) | |

| Output | Alarm output | 2 points each for upper/lower channel |

| 250V AC, 30V DC, 5 A (relay contact? | ||

| 4-20 mA current output | Resolution: 16 bits, 1 point per channel | |

| (Max. load resistance 450?) | ||

| Interface | RS-232C?Transmission distance : Max. 10m? | |

| Model | Main unit | Sensor unit |

| Ambient operating temperature | -10 to 60?? | -5 to 60?? |

| Material | Painted steel | Case: PVC |

| Cable: PVC | ||

| Structure | IP54 equivalent | IP68 equivalent |

| Dimensions | 280?92.5?322 | dia. 80?95 |

| (WxDxHmm) | ||

| Sensor cable length | – | 20 m |

| Max. sensor cable length | – | 100 m *1 |

| Weight | 3.6 kg | 2.2 kg |

Read More Articles :

- Cla-Val Automatic Control Valves

- Dongguan Fuyconn Electronics

- Coltraco Ultrasonics Instruments

- Senko Sensor Technology

- Ryutai Kogyo Instrument