Description

Kruger FDA Series Double Inlet Centrifugal Fans – Forward Curved DIDW centrifugal fan with forward-curved (FC) impellers. The fans are suitable for supply and exhaust applications in commercial, process, and industrial HVAC systems. AMCA Air, Sound, and FEG certified ranges are from 315 to 900.

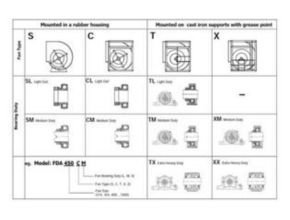

The operating limit of the FDA series is set according to the Class 1, 11, and 111 requirements as defined in AMCA Standard 99-2408-69. The FDA series is available in types S, C, T, or X. FDA series is also available in a twin fan version with two double inlet fans mounted on the same shaft. FC fans are operated at relatively low speeds and are used to deliver large air volumes against relatively low static pressures. The inherently light construction of the curved forward wheel does not permit it to be operated at speeds needed to generate high static pressure.

The typical application range of this type of fan is from 30 to 80% wide open airflow. Selecting an operating point below approximately 30% wide open may place the fan in an area of instability. Similarly, an operating point beyond 80% wide open typically produces noise and inefficiency. The maximum static efficiency is from approximately 50 to 65% and occurs just to the right of the maximum static pressure point on the fan performance curve.

The Specifications of Kruger Kruger FDA Series Double Inlet Centrifugal Fans

Quick Facts

- Size from 160 to 1400 mm

- Capacities to 300,000 m3/h

- Total pressure up to 2400 Pa

- Suitable for use in AHU, packaged unit, and ventilation

Applications

For supply or exhaust applications in commercial, institutional, and industrial HVAC systems.

Testing

Both air and sound performance ratings are based on tests to AMCA210-85 and AMCA300-95 Standards. All wheels are statically and dynamically balanced to ISO1940 and AMCA204 – G2.5 Standards.

The Accessories of Kruger FDA Series Double Inlet Centrifugal Fans

Casing Drain

- This option is available when fans are exposed to the atmosphere or operating in high humidity conditions.

Outlet Flanges

- Outlet flanges are available upon request.

Inspection Doors

- The inspection door is supplied in one of the three positions (P3, P4, P5). Please refer to the FDA product catalog, page 4 for the exact location.

Guards

- Inlet guards, discharge guards and non-drive end shaft guards are available on request.

The Constructions of Kruger FDA Series Double Inlet Centrifugal Fans

Type / Operating Limit

Each fan type has its maximum operating speed and power due to its mechanical design. The operating limit of different fan types of FDA series is set according to the requirement of class I, II, and III limits as defined in AMCA standard 99-2408-69. The FDA series is available in types S, C, T, or X.

Type S

This type is supplied with mounting feet and can be mounted in three different orientations. The construction is mainly for OEM applications which are only subject to testing and approval.

- Fan Size: 160 to 710

- Volume: 1000 to 50000 m3/h

- Total Pressure: up to 1400 Pa

Performance of 160 and 180 are not AMCA licensed.

Type C

This type has a frame fitted on both sides of the fan which gives better strength and rigidity. It allows mounting in four different orientations.

- Fan Size: 160 to 710

- Volume: 1000 to 50000 m3/h

- Total Pressure: up to 1400 Pa

Performance of 160 and 180 are not AMCA licensed.

Type T

This type has a welded frame, giving increased stiffness and rigidity required for higher operating performance.

- Fan Size: 250 to 1400

- Volume: 2500 to 250 000 m3/h

- Total Pressure: up to 1600 Pa

Performance of 1120, 1250 & 1400 is not AMCA licensed.

Type X

The structure is similar to type T but utilizes enhanced bearings to support the higher dynamic load necessary for increased performance.

- Fan Size: 560 to 1400

- Volume: 1500 to 250 000 m3/h

- Total Pressure: up to 1800 Pa

Performance of 1120, 1250 & 1400 is not AMCA licensed.

Wheel

The wheel of FDA is made of galvanized sheet steel forward curved blades.

Housing

Except for 1250 and above, the housing is manufactured in galvanized sheet steel with the housing fixed to the side plates in the “Pittsburgh lock” form system. Housings for 1250 and 1400 are manufactured in mild steel finished with a polyester powder coating finish.

Frame

The frame is manufactured with galvanized angular bars for type “C”. Type “T” and “X”, are manufactured with sections of steel and finished with polyester powder coating.

Shaft

Shafts are manufactured from C45 carbon steel using an automatic process for positioning and cutting the keyways. All dimensional tolerances of the shaft are fully checked to ensure a precision fit. All shafts are then coated with an anti-corrosion varnish after assembly.

Bearings

Bearings used are either deep groove ball bearing type with an eccentric locking collar or an adapter sleeve or spherical roller bearings type sealed at both sides for different duty applications and are classified as below:

Except for TX, XX, and UX extra heavy-duty bearings, all bearings are lubricated for life and maintenance-free. If relubrication is necessary, it is recommended to use lithium-base grease suitable for all temperatures within the operational limits.

Balancing Quality

All wheels are statically and dynamically balanced to ISO1940 and AMCA 204 – G2.5 standards. All fans after assembly are trim-balanced to ISO1940 and AMCA 204 – G2.5 standard. Clean room application fans with a balancing grade of G1.0 are available upon request.

Reference: www.krugerfan.com

Read More Articles :

- AquaMotion AM5-F1 Cast Iron Circulators

- Greystone TNAP Temperature Sensor All Purpose Network

- Greystone Energy Systems

- Quincy Compressor QGV Series Variable Speed Air Compressor

- OBL Blackline XRN Series Hydraulic Diaphragm Metering Pumps

- Deep Sea Electronics DSE103 Speed Switch Control

- Adam Equipment Crane Scales IHS Series

- Apollo 108FC Fire Pump Relief Valve

- Acadiana Pump Stroke Counter or Rate Meter

- Kaidi Conveyor Belt Safety