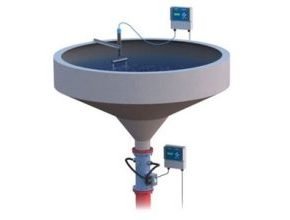

Description

Delta Mobrey MSM400 Ultrasonic Solids Monitoring and Control System continuously monitors the suspended solids or sludge density contained in, or flowing from, a clarifier or settlement tank during de-sludging. continuously monitors the suspended solids or sludge density contained in, or flowing from, a clarifier or settlement tank during de-sludging. To run at your full potential and maximize process control, you need reliable instrumentation throughout your facility.

Many years of practical experience have shown that the measurement of ultrasonic attenuation in a slurry is directly proportional to the percentage of suspended solids. The MSM400 system uses this principle to produce a digital display of the suspended solids measurement.

Delta Mobrey MSM400 Features:

Control unit

- Bright local display of the measured value and statuses

- 4–20 mA / HART output signal of measured value

- Two SPDT (single-pole-double-throw) relays for control and alarm indication purposes

- A digital trigger input can perform various control actions

- Comes complete with a range of user-selectable calibration settings for simple initial set-up, but can also be calibrated against samples analyzed for % solids in a laboratory

- Provides the automatic control sequence to start a pump or control a valve for sludge or settled product removal

- Local programming of the control unit is supported using the integral keypad and an easy-to-navigate menu structure

- Remote programming and monitoring are supported using a Field Communicator or a smart wireless THUM™ adapter

- Auto-selection of AC or DC power supply, allowing back-up if one power supply fails

Intrinsically safe sensors:

- Dual-operating-frequency gap sensors, 1 MHz or 3.3 MHz

Delta Mobrey MSM400 control unit Specification:

Physical:

- Mounting style

- Wall mount (brackets included)

- Six mounting holes, 0.2 in. (5 mm) diameter

- Display: Integral 32 x 122 pixels LCD with backlight, providing up to four lines of characters

- Keypad: Integral membrane keypad with six buttons for menu system navigation and configuring the application

- Conduit/cable entries

- Six conduit/cable entry positions, pre-drilled at the bottom of the enclosure

- Supplied with three M20 glands and three M16 glands Dimensions

- Construction materials

- ABS enclosure with clear polycarbonate lid

- 304-grade stainless steel cover-fixing screws

- UV-resistant polycarbonate membrane keypad

- Nylon cable glands and blanking/stopping plugs

Electrical

- General

- Cage clamp terminal blocks in a separate compartment

- Maximum wire size is 2.5 mm2 (12 AWG)

- Power supply input connections

- Alternating Current (AC) mains and Direct Current (DC) terminal connections on each control unit for external supply

- Auto-selection of AC or DC supply, allowing back-up if one power supply fails

- AC power supply requirements:

- 115 or 230 Vac ±15% (switch selectable)

- Power consumption: 10 VA nominal

- Fuse (F1): 200 mA (T), 5×20 mm, 240 V

- DC power supply requirements:

- 15 to 30 Vdc, 24 Vdc nominal

- Power consumption: 6 W nominal

- Sensor input connections

- Captive screw terminal block for 1 x ultrasonic gap sensor

- 1 MHz or 3.3 MHz operating frequency auto-selection

- Digital input connections

- Accepts two 5 Vdc trigger input signals

- 5 Vdc provided by the control unit

- Other input connections

- Field communicator connection points

- Current output connections

- Nominal signal range 4–20 mA (default) or 0–20 mA, software selectable

- Full output range (linear): 3.8 to 20.5 mA

- Load: maximum resistance is 1 K Ohm at 22 mA

- Maximum applied voltage: 48 Vdc

- Isolated from other terminals to 500 Vdc

- Update rate (software): 10 times every second

- Relay output connections: Two SPDT (single-pole-double-throw) relays, rated 5 A at 240 Vac resistive

- Environment:

- Ambient temperature: –22 to 131 °F (–30 to 55 °C)

- Relative humidity: 95%

- Enclosure rating: P65 indoor and outdoor

Download Data Sheet: ultrasonic solid monitoring control system

Ref: delta-mobrey.com

Another Article:

- Delta Mobrey Differential Pressure Measurement

- Delta Mobrey 301 Series Differential Pressure Switch

- Delta Mobrey 381 Series Differential Pressure Switch

- Delta Mobrey 209 Series Pressure Switch

- Delta Mobrey Transmitter and Gauge

- Delta Mobrey Level Measurement

- Delta Mobrey Flow, Steam and Water, Conductivity Probe and Accessories

- Delta Mobrey Pressure Measurement

- Delta Mobrey 204 Series Pressure Switch

- Delta Mobrey 303 Series Differential Pressure Switch

- Delta Mobrey 772 Series Temperature Switch

- Delta Mobrey CS 2/4 Series Pressure Switch

- Delta Mobrey 734 Series Temperature Switch

- Delta Mobrey 304 Series Differential Pressure Switch