Description of Krohne BM26A-8000 Optiflex 7200 C

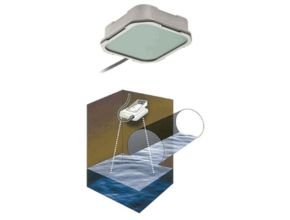

The BM26A-8000 is a magnetic level indicator (MLI) for redundant level measurement in liquid applications. It comes in two versions: BM26A-8000-TWIN and BM26A-8000-BI. The BM26A-8000-TWIN consists of a double measuring chamber with one chamber featuring a flapper indication and the other one – equipped with a level transmitter (TDR guided radar, FMCW radar or displacer) – acting as a bypass chamber. The BM26A-8000-BI features a unique measuring chamber with two compartments, one for the OPTIFLEX 7200 transmitter probe and one for the float moving next to it.

Features of Krohne BM26A-8000 Optiflex 7200 C

- Combined technology for redundancy

- Can be fitted with OPTIFLEX 7200 or OPTIFLEX 8200 guided radar (TDR), OPTIWAVE 7400 radar (FMCW), or BW 25 displacer level transmitter

- Also available as a TWIN version with a dual bypass chamber connected adjacently

- Rugged metallic design – no maintenance

- Large choice of materials e.g. 316L, 304L, alloy C276, alloy 625

- Highly visible flaps housed ina hermetically sealed glass tube (IP68)

- Accuracy from ±2 mm / ±0.08? with OPTIFLEX and OPTIWAVE level transmitters

Application of Krohne BM26A-8000 Optiflex 7200 C

General

- Redundant measurement in liquid applications up to +400°C / +752°F

- Interface measurement

- Safety-related applications up to SIL2/3

Oil and Gas Industry

- Level control on process and storage tanks for oil and other hydrocarbons

- Oil/water interface measurement in high- and low-pressure separators

Chemical industry, petrochemical industry

Redundant level control and interface measurement of various chemicals and refined products such as:

- Refined products (e.g. gasoline, ethylene etc.)

- Toluene, xylene, naphtha, gas condensate

- Heat transfer fluids (e.g. Therminol®) and glycol

- Alcohols

Power Industry

- Redundant level monitoring in the steam cycle of power plants (e.g. steam condensate, boiler feedwater, etc.)

- Level monitoring of heat exchangers

Specification of Krohne BM26A-8000 Optiflex 7200 C

General Information

| Product Type | Level indicator |

| Product family name | BM |

| Product positioning | For liquids in redundant measurement |

| Measurement principle | Radar (FMCW), Displacer, Guided radar (TDR), Float |

| Level measurement type | Continuous measurement |

| Contact to the measured medium | Yes |

| Interface measurement | Yes |

| Redundancy | Yes |

| Measured media | Liquids |

| Measuring range (liquids) | 0.3…5.5 m/ 1…18 ft (other on request) |

| Measuring point | Bypass |

Operating Condition

| Process temperature | Version with OPTIFLEX 7200: -50…+250°C/ -58…+482°FVersion with OPTIFLEX 8200: -50…+315°C/ -58…+599°FVersion with OPTIWAVE 7400: -50…+200°C/ -58…+392°F Version with BW 25:

|

Materials

| Gaskets | Depending on the selected device configuration |

| Wetted parts | Depending on the selected device configuration |

Process connections

| Flange connections | EN (1092-1): DN15…50 ASME (B 16.5): ½…2? |

Approvals/Standards

| Certificates/Approvals Ex | ATEX, IECEx |

| Certificates/Approvals Safety | SIL 2/3 |

Communication

| Analog outputs | 4…20 mA |

| Discrete outputs | Limit switches |

| Digital outputs | FOUNDATION™ fieldbus, HART®, Profibus-PA |

Accuracy

| Accuracy (liquids) | Indicator: ±10 mm/0.39 in (optional: ±5 mm / 0.2 in with LT40)OPTIFLEX/OPTIWAVE: ±2 mm /0.08 in |

For More Information and Price: Krohne BM26A-8000 Optiflex 7200 C

Read More Articles:

- Microsensorcorp MPM416WK Submersible Level Transmitter

- Microsensor Corp MPM4893W Level Transmitter

- Microsensor Corp MPM436W Submersible Level Transmitter

- Microsensorcorp MPM4810 Level Transmitter for High Temperature Up To 125?

- Microsensorcorp MPM489WZ1 Level Transmitter