Description

OMNI Flow Computers Established in 1990 designed, developed, manufactured, and supported the OMNI flow computer out of its Sugar Land, Texas headquarters. As the largest independent manufacturer of flow computers, OMNI is the preferred choice of oil and gas companies worldwide.

About OMNI Flow Computers

When the first OMNI was released in 1991, its innovative technology and unrivaled reliability quickly became the industry standard. Today, OMNI flow computers are estimated to be connected to over 50,000 custody transfer flow meters located in more than 100 countries. OMNI flow computers are used in every aspect of the oil and gas industry, from production LACT units, oil transportation and gas transmission pipelines, oil terminals, refineries, gas and petrochemical plants, ship-loading terminals, and offshore production platforms and processing facilities (FPSOs).

OMNI is known for high-quality flow computers that deliver uninterrupted performance within a long lifecycle. Our production line and assembly operation enables OMNI to deliver high-demand standard hardware products that can be further customized to fit unique specifications. There is a wide range of configurable operational functions that do not require custom programming. Judge for yourself our reliability, support and longevity against commodity products available in the marketplace.

Vision and Mission

As a privately held company, we answer to our customers. We are committed to excellence and dedicated to providing products, services, and support of the highest caliber.

ISO Cercification

ISO 9001:2015 provides a set of requirements that must be in place to have a quality management system regardless of the organization’s size, product or service line, or public or private status. Certification to the standard is voluntary, and organizations must complete a rigorous auditing process by a third-party registrar.

The Products of OMNI Flow Computers

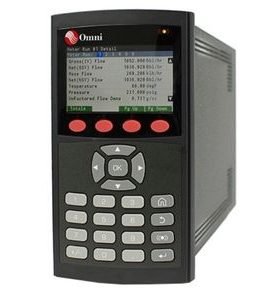

OMNI 4000/7000 Series

The OMNI Series 4000/7000 flow computer delivers reliable, and fully traceable measurement of gas and liquid applications. As the most secure flow computer available, the 4000/7000 is ideal for custody transfer and fiscal measurement applications.

The OMNI Series 4000/7000 flow computer combines decades of metering experience and delivers primary liquid and/or gas US customary and metric calculations in a single program. It parallels the hugely popular OMNI 3000/6000 to provide the same reliability and project lifecycle guarantees. The 4000/7000 is ideal for pipeline systems and critical infra-structure projects where cyber-security and programming control are core requirements.

The Series 4000/7000, just like every OMNI built in the last 25 years, is factory-programmed and user-configurable. We believe that our program testing prior to factory release exceeds any project-oriented, customized programmable device. Only OMNI provides secure factory programming, testing, and verification. Only field configuration is required to install, operate, and maintain the OMNI 4000/7000.

With full programming traceability from factory to operation, the OMNI 4000/7000 is the only flow computer to have received the European MID/WELMEC WG7.2, issue 6, extension D approval. This means that any programming modifications and upgrades after original factory release are controlled and traceable in accordance with metrology regulations. OMNI is an assurance partner for your Management of Change.

Benefits

- Enhanced functionality with a simplified user interface and powerful software

- Powerful, robust, embedded, real-time operating system

- Fast access to critical data when you have remote connections like PLCs, DCSs, or SCADA systems

- 365+ days of batch storage

- Searchable database

- Enhanced security for protection against cyber intrusions

- Individual user IDs and passwords for enhanced security

OMNI 3000/6000 Series

The OMNI 3000/6000 Series of flow computers consistently delivers reliability and longevity for a low total cost of ownership that is recognized throughout the world. The OMNI 3000E/6000E flow computer – including an enhancement over the basic OMNI 3000/6000 Series – offers improved security, enhanced software capabilities, and improved auditing and alarm functionality.

With its fast one second power-up recovery, field proven reliability, longevity, and usability, the OMNI 3000E/6000E offers the low total cost of ownership that OMNI is recognized for delivering. The 3000E/6000E exceeds all requirements for data processing, accuracy, and calculation cycle time for all recognized standards bodies, including API, ISO, OIML, and AGA.

When choosing between the OMNI 3000 and OMNI 6000 flow computers

The key question to ask is: How many meter runs do you need? The OMNI 3000 supports up to two meter runs. The OMNI 6000 gives you four. Beyond the number of meter runs, other considerations include:

- How many and what types of field equipment inputs and outputs will be connected?

- What communications connections will you require?

- Will you be measuring hydrocarbon gas or liquid or some other fluid?

- Will you measure in metric (SI) or U.S. customary units?

- What is your preferred installation style?

The OMNI 3000 is typically used for single-liquid or dual-gas meter-run applications. It accepts two field I/O modules (combo modules). The OMNI 3000 comes with one 12?channel digital I/O m

The OMNI 6000 accepts up to 24 input signals using six field I/O modules (combo modules), including two serial SV modules. It is typically used for up to four meter-run applications. The OMNI 6000 comes with two 12?channel digital I/O modules and up to three communications modules (either serial or Ethernet, or a mix of both)

The OMNI 3000E/6000E Flow Computer offers:

Improved Security

- Enhanced security features mean tighter control over how both personnel and third-party systems can access the flow computer.

- Up to 16 individual users, with individual login and password

- Different permission rights for each user

Improved Auditing and Alarm Functionality

- The enhanced system captures more complete data from all configuration changes and alarms, including date and time stamps, origin, and totals at the time of the change or alarm.

- Up to 1000 alarm events

- Full auditing

- Configuration check-sum to monitor configuration changes

Enhanced Features

- Twice as many liquid products

- Twice as many Boolean and Variable statements

Enhanced Software Capabilities

- OMNICOM software has been updated to accommodate the security, audit, and alarm firmware updates. It also incorporates time-saving features that allow direct-paste functionality of registers, eliminating the need for a manual.

OMNICONNECT

Designed for an effortless user experience, OMNICONNECT™, the easy-to-use software that is licensed with the OMNI Series 4000/7000, incorporates an enhanced level of configurability into a robust, fast and highly responsive system.

OMNICONNECT® is the Windows-based PC software that offers an enhanced level of configurability with the OMNI 4000 and 7000 flow computers. Developed on a real-time operating system, OMNICONNECT is robust and can keep up with the demands of advanced data management. OMNICONNECT is highly responsive and completes data transfers on networks, or directly, with rapidity.

OMNICONNECT allows users to perform multiple tasks on the OMNI 4000/7000. It simplifies both offline and online flow computer configuration, and allows the user to test some operations, such as quality monitoring in gas systems, and batching, and proving in liquid systems. Port and user security settings can be imported and then exported into other OMNI flow computers when a duplicated security structure is desired.

OMNICONNECT® features an easy-to-use interface that offers more flexibility in customization and makes it simple to navigate between menus. Existing OMNI users, already familiar with OMNICOM, will recognize the similarity in look and feel. Therefore, minimal training to learn the extended capabilities of OMNICONNECT is required. No other high-level programs are permitted to make changes or modifications to the OMNI firmware. This would contravene the requirements of WELMEC approvals. A standard OMNICONNECT software license is included with each 4000/7000 OMNI flow computer. Use is subject to the terms outlined in the OMNI software license agreement.

Key Benefits :

- Integrated flow computer Modbus Database Browser

- Supports Secure Socket Layer (SSL) Ethernet connections

- USB, Serial, and Ethernet access to flow computer

- Access to multiple flow computer sites

- User-configurable custom data screens for real-time data display

- Ribbon Bar with large icons for ease of use

- Historical Record Browser for retrieving Batch, Daily, Prove, and Detailed Daily reports

- Optional Quick Start dialog

- Graphical User Interface to manage flow computer security

- Update flow computer firmware over USB connection

- GUI controls enabled/disabled by User Security Permissions when online

- GUI for calibration of flow computer I/O

- Configuration data validation with Tooltip integration for User notification

- Online and offline configuration

- Windows 10 support

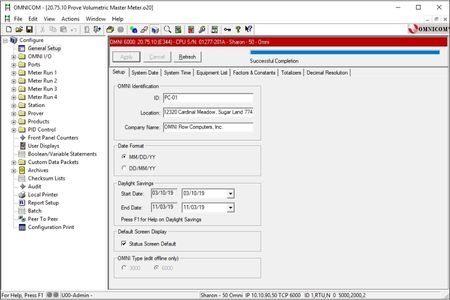

OMNICOM

OMNICOM® is the companion PC?based software that enhances the use of OMNI 3000/6000 Series flow computers. This single Windows® program is all you need to perform any task on the OMNI.

OMNICOM® is the flexible, user-friendly, Windows-based software that simplifies operation of your OMNI flow computers. With online and offline capabilities, OMNICOM allows you to monitor quality, track diagnostics, and configure the flow computers without disrupting operations. OMNICOM offers customizable reports and multiple-site access. It is all you need to manage your OMNI flow computers.

Designed around the OMNI operating system, OMNICOM emulates the front-panel keypad entries necessary to configure OMNI 3000/ 6000 series flow computers and controllers. OMNICOM simplifies configuration with full-color menus and extensive F1 Help. Many key configuration parameters have built-in safety limits to protect you from accidental errors that could lead to faulty measurement.

OMNICOM® allows you to perform operations such as quality monitoring in gas systems, and batching and proving in liquid systems. Valuable diagnostic and data screens are also available. Whether you’re simply changing one alarm limit or adding a whole new meter run, OMNICOM doesn’t require the OMNI to be taken offline. All your changes can be made online, with no interruption to your business.

Finally, integrated into OMNICOM is WinPanel, a PC-based software interface that allows you to remotely control multiple flow computers through a serial or Ethernet network connection. WinPanel replicates all the functionality of the flow computer’s front panel on your computer desktop and can be accessed through OMNICOM.

Key Features :

- Online and offline configuration

- Local and remote access

- Simple operation

- Multiple-site access

- Extensive F1 Help

- Built-in safety limits

- Extensive communications logging and debugging

- Customizable reports

- Integrated WinPanel

- Windows 10 support

Source : omniflow.com

Read More Articles :

- WYATT Engineering – Intelligent Flow Measurement

- Degson Heavy Duty Electrical Connector

- Pneumatrol Valve and Solenoids Pneumatic

- Turck Automation Systems

- Tognella Valves Production Company